SMT·PCBA | Computer Peripheral Electronics Core Manufacturer

Our commitment to excellence in Keyboard OEM & ODM services sets us apart from competitors and fosters long-term partnerships.

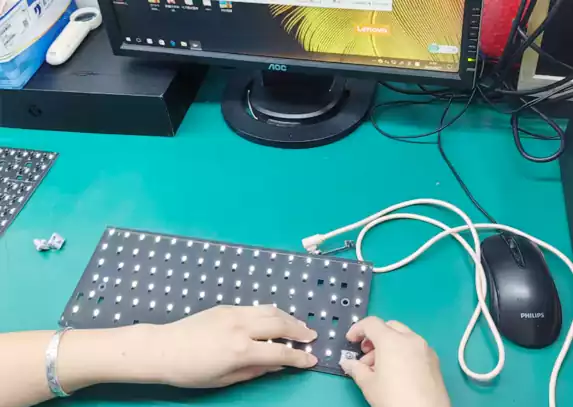

- Specialized in SMT Assembly and PCBA Manufacturing

- Over 20 years of focus on PCBA SMT assembly for computer peripherals—providing end-to-end SMT delivery for computer peripherals!

20 Years in Mechanical Keyboards & E-Sports Peripherals | One-stop SMT, Assembly & Testing for Small & Large-Scale Production

We have extensive experience in Keyboard OEM & ODM manufacturing, enhancing product output and quality.

A national high-tech enterprise specialized in SMT assembly and PCBA manufacturing.

Committed to precision manufacturing and customer-centricity, we support fast small-batch & stable large-scale production, offering one-stop high-reliability PCBA solutions for consumer, automotive, industrial control and medical electronics, aiming to be your trusted PCBA partner. Boasting a 600㎡ cleanroom, 3 intelligent production lines and imported Yamaha SMT, KIC thermal profiler & Omron AOI equipment, ISO9001 certified with strict SOPs, we achieve 5 million monthly SMT placements, supporting MOQ 50 small-batch trials and 100,000+ mass production. Our premium keyboard OEM/ODM capabilities adapt to electronic manufacturing needs, with a yield rate of over 99.9% and 30% shorter mass production cycles for customers.

What is a One-Stop PCBA Solution?

PCBA integrates PCB manufacturing, component placement and finished product assembly. Our one-stop PCBA service covers the full journey from demand communication to delivery and after-sales, eliminating multi-supplier coordination hassle, achieving a demand-solution-delivery closed-loop service, and effectively resolving pain points of multi-party communication, cumbersome processes and fragmented responsibilities.

With "precision manufacturing + flexible PCBA services" as our core advantage, we turn every PCBA into a reliable cornerstone for customers' electronic products.

Our Philosophy

We uphold precision manufacturing and customer-centricity, adhering to high yield, fast delivery and strong adaptability to provide reliable custom SMT/PCBA solutions that help you cut costs, boost efficiency and build core competitiveness. Focusing on SMT R&D and premium quality, we deliver flexible services to ensure stable PCBA quality for your products. Committed to your success, we solve full-process pain points, enable fast small-batch response and stable large-batch delivery through precision placement, intelligent management and cost optimization, and innovate with you to drive industry development.

Why Choose Us?

- SMT is a critical process for mechanical keyboards and peripherals, directly ensuring PCB & main control board quality and stability. Our professional SMT team specializes in keyboard component placement, with PCB assembly parameter fine-tuning and process optimization capabilities, supported by advanced imported SMT equipment for keyboard production. Choose our OEM/ODM service for premium quality and full support.

- Equipped with high/medium-speed Yamaha SMT machines (YS12, YS24) for efficient assembly of keyboard/mouse peripheral PCBs, precision screen printers for circuit printing, reflow ovens for stable soldering of chip/sensor parts, and AOI inspectors for strict PCBA solder joint and defect checks.

- We have standardized SOPs for peripheral PCBA SMT processes, and fully deliver accurate, stable SMT placement and testing for all types of computer peripheral PCBA boards.

Our SMT workshop features Class 10,000 cleanliness, constant temperature of 23±2℃ and humidity of 45±5%, effectively preventing dust interference and ensuring high-precision PCB assembly. We operate 3 intelligent SMT production lines (2 high-speed, 1 medium-speed) with a full workflow of screen printing → placement → reflow soldering → AOI inspection, where high-speed lines support large-batch production and medium-speed lines cater to small-batch custom processing. We hold ISO9001:2015, IATF16949:2016, ISO13485:2016, RoHS 2.0 and REACH certifications, complying with strict industry quality, reliability and environmental standards.

We provide end-to-end computer peripheral OEM (PCB design, sourcing, SMT, assembly, packaging), core keyboard OEM/ODM, full-process quality control, innovative reliable solutions, your trusted preferred partner.

PCBA assembly equipment

We offer one-stop computer peripheral OEM (PCB design, sourcing, SMT, inspection, assembly & packaging), professional keyboard OEM/ODM with full-process quality & efficiency, reliable innovative solutions for diverse needs, your top industry partner.

We offer flexible cooperation models for startup clients

We customize keyboard OEM/ODM solutions for your success, offer one-stop full-process PCB design, SMT, assembly & packaging, cut production costs by 10%, with proven quality, innovation and reliable track record.

We customize keyboard OEM/ODM solutions for your success, offer one-stop full-process PCB design, SMT, assembly & packaging, cut production costs by 10%, with proven quality, innovation and reliable track record.

Our SMT lines provide high-efficiency, precision SMT placement and DIP insertion, with MES-enabled real-time production monitoring and data analysis, plus PCBA three-proof coating, fully meeting diverse PCBA needs.

We conduct customized PCBA electrical performance, aging and reliability tests per your specs, and offer professional support for CE, FCC, RoHS certifications.

Our MES system enables real-time production monitoring & full PCB traceability for total transparency; intelligent temperature control customizes reflow profiles, achieving ≤5% solder void rate for precision chips; Class 10,000 cleanroom eliminates dust, ensuring high-precision PCB soldering.

The precision in our Keyboard OEM & ODM processes allows us to deliver outstanding results consistently.