Total Quality Control – For Reliable Keyboard Performance

- Keyboard factory's professional modern R&D laboratory

- Our professional testing equipment delivers accurate experimental data to support computer peripheral product R&D and peripheral quality analysis!

Professional Lab Testing, Global Compliance & End-to-End Quality Assurance.

We specialize in providing high-quality OEM & ODM Keyboard solutions tailored to your needs.

Quality stems from details.

Zhuhai Hengcang Electronics Technology Co., Ltd., a professional mechanical keyboard manufacturer and premium keyboard factory specialized in keyboard OEM & keyboard ODM, OEM & ODM keyboard, commercial keyboard production and custom terminal peripheral manufacturing, has built standardized IQC management for strict raw material quality control. Our IQC team executes standardized incoming material inspections, responds promptly to quality abnormalities for smooth production, and conducts root cause analysis to prevent recurrence. We adopt cross-departmental collaboration to address production quality issues and customer complaints with targeted solutions, boosting satisfaction and maintaining long-term partnerships with renowned clients including WAYCOS, MSTONE and GRG Banking Group. Regular professional training on switch inspection and ISO 9001:2015 implementation is provided to enhance IQC staff’s material risk identification capability, solidifying the quality foundation of our keyboard OEM & ODM business.

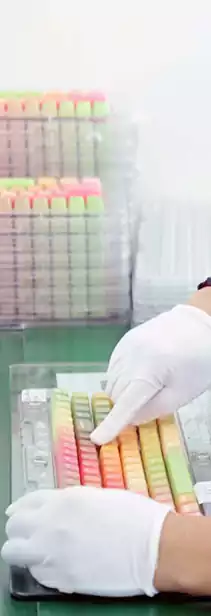

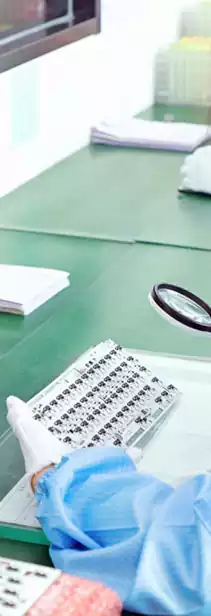

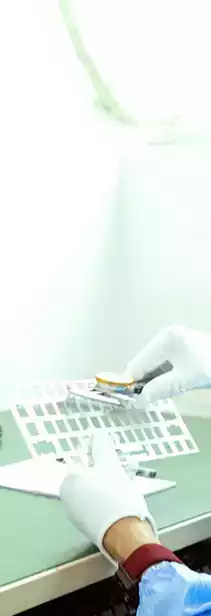

- Precise Inspection & Selection: Strictly screen and precisely inspect core raw materials, laying a solid foundation for peripheral product quality.

- Unshakable Commitment: We hold an unwavering commitment to product quality—steadfast across esports mechanical keyboards, commercial keyboards, and custom terminal peripherals—to meet customers' strict requirements.

- We don’t just say “Quality First”—we live it. For keyboards and peripherals, quality is the make-or-break bedrock of a great product, and it’s also the reason we stay ahead of the competition.

- Pursuit of Excellence — There’s no finish line when it comes to improving product quality for us. We’re constantly fine-tuning the switch feedback of esports keyboards and enhancing the long-term durability of commercial models, all to live up to the strict standards of customers around the world.

- Meticulous Detail Control: In the quality control of esports mechanical keyboards and commercial keyboards, every detail—from switch feedback to key consistency—is handled with meticulous care.

Our keyboard factory and professional mechanical keyboard manufacturer strictly inspect core raw materials for OEM & ODM keyboard per keyboard OEM & keyboard ODM custom standards & drawings, blocking non-conforming materials from production. We follow inspection plans to avoid delays, send performance materials for professional testing with real-time tracking, and mark/isolate defective materials to prevent them from entering assembly.

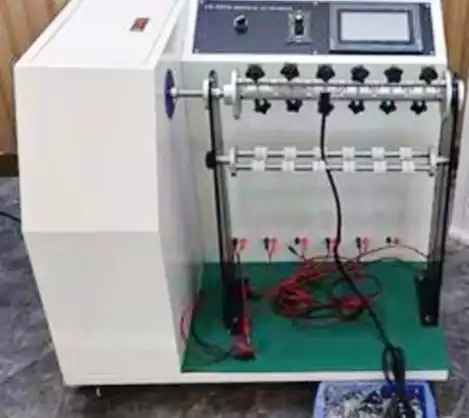

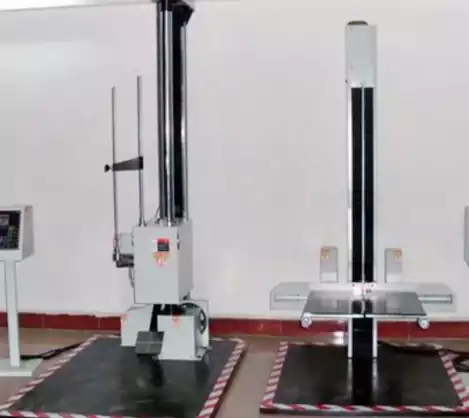

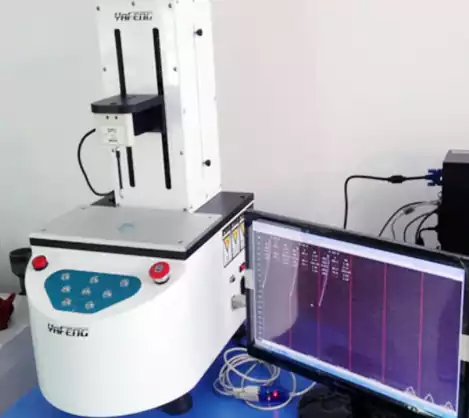

Professional Modernized Quality Testing Laboratory

Zhuhai Hengcang’s keyboard factory features an industry-leading lab for full product quality testing, equipped with custom key equipment covering switch performance/durability, extreme environment adaptability, RoHS compliance, reliability, anti-static and keycap abrasion tests. Upholding "Quality and Service", we ensure all keyboards and peripherals meet stringent high-quality standards.

Introduction to the Full-Process Quality Control of Keyboards:

Our keyboard factory applies full-process QC to peripherals, strictly complying with global standards (ROHS, PAHs, REACH, CE, FCC) to ensure product safety, eco-friendliness and stability, enabling smooth market access to Europe, North America and Southeast Asia.

1. Raw Material Procurement and Inspection

Our core keyboard raw materials include plastics, circuit boards, switches and keycaps. We strictly ensure all materials comply with global environmental standards (RoHS, PAHs, REACH), and send all materials to our factory’s advanced lab for testing to verify non-toxic, harmless and odorless properties, laying a solid foundation for the green safety of our keyboards.

2. Production Process Control

The production process covers mold manufacturing, circuit board soldering, component installation and final assembly. We implement strict quality control at every stage – inspecting mold precision, solder joint firmness and component compatibility, identifying and resolving quality issues early to ensure consistent quality of finished esports mechanical keyboards and commercial keyboards.

3. Testing and Inspection

All finished keyboards undergo rigorous testing for stable performance and premium quality, with strict CE/FCC compliance verification for market access. Test data is systematically recorded and analyzed to adjust production parameters, optimize performance and ensure consistent quality.

4. Packaging and Shipment

Hengcang conducts strict pre-shipment inspection, only qualified keyboards are shipped. We comply with RoHS/PAHs/REACH/CE/FCC for global access, implement full-process QC from procurement to shipment, ensuring superior quality and global compliance.