In mechanical keyboard manufacturing, keycap installation has long been a critical bottleneck limiting production efficiency. Traditional manual keycap pressing is not only slow but also struggles to ensure consistency. The automatic keycap press machine launched by Hengcang Electronic Technology has completely transformed this scenario.

This automated equipment, equipped with precision mechanical structures and intelligent control systems, enables high-precision, high-efficiency keycap installation—boosting keyboard production efficiency by over 300% and reducing the defect rate to below 0.1%.

01 Technical Principle: How Automation Achieves Precision Keycap Press-Fitting

The automatic keycap press machine replaces manual labor with automated mechanisms to pick, place, and press-fit keycaps. The equipment adopted by Hengcang integrates mechanical structures, electronic control systems, and sensor technology, enabling high-precision and high-efficiency keycap press-fitting operations.

The core working principle of the equipment consists of three parts: the feeding mechanism, control unit, and press-fitting mechanism.

- Feeding Mechanism: Responsible for automatic alignment and conveying of keycaps. It uses a vibration plate to sort messy keycaps into an orderly arrangement and convey them in a fixed direction. Hengcang’s feeding system can automatically screen out special-shaped keycaps, ensuring only standard-compliant keycaps enter the press-fitting process.

- Control Unit: Acting as the "brain" of the equipment, it uses PLC (Programmable Logic Controller) programming to precisely command the actions of the execution mechanism. This system controls the operation of motors or cylinders, driving slides to move along the XYZ axes for accurate keycap positioning. Operators can intuitively set parameters and monitor the equipment via a touchscreen.

- Press-Fitting Mechanism: Composed of a press rod, positioning jig, and pressure sensor, it performs the final press-fitting operation. Hengcang’s equipment is equipped with a high-precision pressure control system, ensuring uniform pressing force for each keycap—preventing loose keycaps (from insufficient pressure) or damaged keyboard structures (from excessive pressure).

02 Core Structure & Workflow

The mechanical structure of Hengcang’s automatic keycap press machine mainly includes four parts: the frame, transmission system, positioning system, and press-fitting system.

- Frame: Provides support and stability for the entire equipment. It is usually made of high-strength aluminum alloy profiles to ensure stability during high-speed operation.

- Transmission System: Converts the rotational motion of the motor into precise linear motion. Common methods include lead screw transmission and belt transmission.

- Positioning System: The key to ensuring precise keycap press-fitting. Hengcang’s equipment adopts visual positioning technology—high-definition cameras capture the positions of keycaps and keyboards, and the control system calculates deviations and adjusts positions accordingly. This technology achieves micro-level positioning accuracy, far exceeding the limits of manual operation.

- Press-Fitting System: Realizes smooth keycap pressing through a precision force control device. The equipment automatically adjusts the press-fitting force according to the specifications of different keycaps, ensuring uniform force application and avoiding keycap damage or keyboard structure damage caused by uneven force.

The workflow starts with keycap feeding:

- Operators pour a large number of keycaps into the equipment’s feeding mechanism.

- The vibration plate automatically aligns the keycaps, arranging them in a unified direction.

- The aligned keycaps enter the conveyor system and are transported to the press-fitting position.

- Meanwhile, the keyboard is placed on a positioning jig, and its position is accurately determined by the positioning system.

- The press-fitting head picks up the keycap from the feeding mechanism, moves to the top of the keyboard, and performs the press-fitting action after precise positioning.

The entire process is completed in seconds, with efficiency far surpassing manual operation.

03 Technological Innovations & Advantages

Hengcang’s automatic keycap press machine demonstrates technological innovations in multiple aspects, giving it significant advantages in the keyboard manufacturing field.

- Flexible Production Capability: A major highlight of the equipment. With simple program adjustments, a single machine can handle keyboards of different specifications and layouts (e.g., 60%, 80%, and full-size). This flexibility is particularly suitable for the current keyboard market’s demand for small-batch, multi-variety production.

- Intelligent Quality Inspection System: Ensures production quality. During the press-fitting process, the equipment monitors the pressure curve in real time—any abnormalities trigger an immediate alarm. The system records press-fitting data for each keycap, forming a complete quality traceability record to support subsequent quality analysis.

- Modular Design: Simplifies equipment maintenance and upgrades. Key components (e.g., press-fitting heads, feeding mechanisms) use standardized interfaces. In case of failure, they can be quickly replaced, significantly reducing equipment downtime.

Compared with traditional keycap installation methods, the automatic keycap press machine has obvious advantages in efficiency, precision, and consistency:

- Efficiency: Manual keycap pressing takes 2–3 seconds per keycap, while the automatic equipment reduces this to less than 0.5 seconds. For a 104-key keyboard, the automatic machine completes installation in approximately 1 minute, compared to 5 minutes for manual operation.

- Precision: Hengcang’s equipment achieves precise adjustment of press-fitting force, ensuring uniform tightness for every keycap. Traditional manual installation struggles to maintain consistency, while the automated equipment eliminates quality fluctuations caused by human factors.

04 Application Scenarios & Benefit Analysis

Hengcang’s automatic keycap press machine is widely used in mechanical keyboard production lines, especially in scenarios requiring high production efficiency and product quality.

- Large-Scale Production: The equipment significantly improves production efficiency and reduces labor costs. One machine can replace 3–5 workers and operate 24/7, greatly enhancing production benefits. For a factory producing 100,000 keyboards per month, the introduction of automatic keycap press machines saves millions of yuan in labor costs annually.

- High-End Custom Keyboards: Ensures product consistency and high quality. During manual keycap installation, inconsistent operation force and angle easily lead to uneven keycap height or inconsistent tactile feedback. The automatic equipment, through precise program control, guarantees uniform installation status for every keycap.

- Special Keycap Installation: Demonstrates irreplaceable value in installing special-shaped keycaps, large keycaps, or keycaps made of special materials. The equipment automatically adjusts press-fitting parameters based on keycap characteristics, avoiding damage to keycaps or keyboards caused by improper operation.

From an investment return perspective, although the initial investment in automatic keycap press machines is relatively high, long-term economic benefits are significant. Taking a real case of Hengcang’s customer: after introducing the equipment, the defect rate of the keyboard production line dropped from 1.5% to below 0.3%, production efficiency increased by over 200%, and the equipment investment was recovered within 1–2 years.

05 Future Development Trends

With the continuous development of industrial automation technology, Hengcang’s automatic keycap press machine is evolving toward greater intelligence and efficiency.

- Human-Machine Collaboration: An important future direction. Traditional automated equipment usually requires strict safety isolation, while the next generation of keycap press machines will focus more on the safety of human-machine interaction, enabling closer collaboration between humans and machines.

- IoT Integration: Will enhance equipment intelligence. Real-time monitoring of production data, equipment status, and energy consumption provides a scientific basis for production optimization and equipment maintenance, further improving production efficiency and product quality.

- AI Application: Another key future trend. Through machine learning algorithms, the equipment can self-optimize parameters and predict maintenance needs, further enhancing the intelligence of keyboard production. For example, the equipment can predict the optimal keycap press-fitting parameters based on historical data to achieve adaptive press-fitting.

- Increased Flexibility: As demand for personalized customization grows, automatic keycap press machines will become more flexible. Future equipment will handle more types and specifications of keycaps, meeting the market’s increasing demand for personalized keyboards.

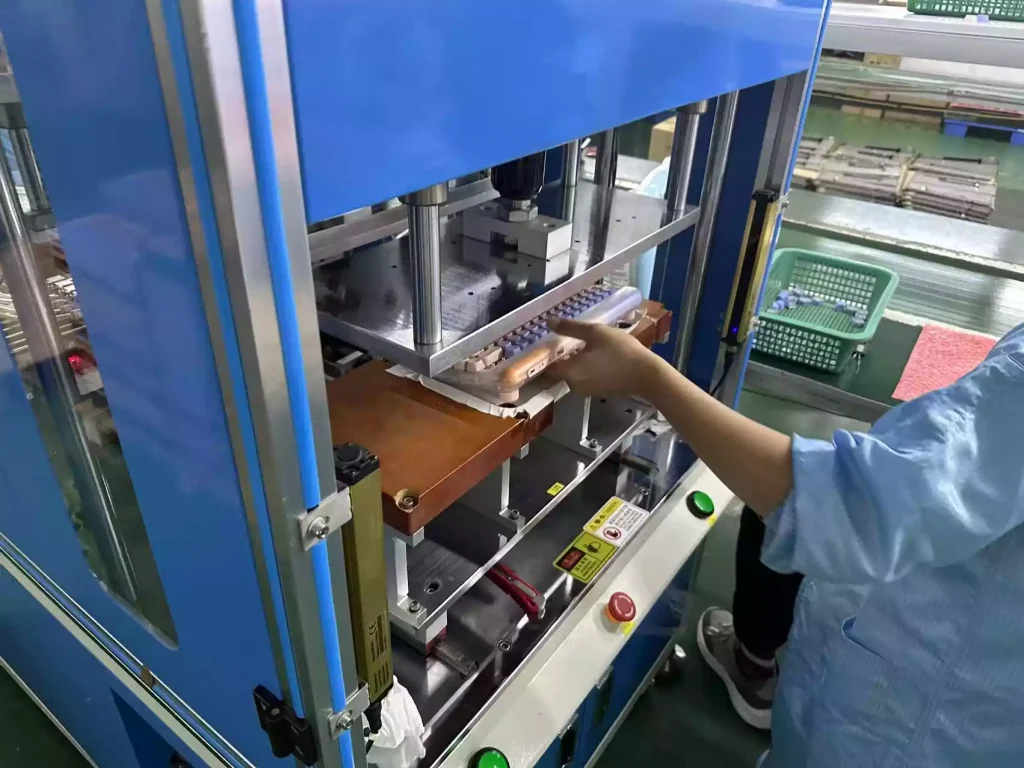

In Hengcang Electronic’s production workshop, automatic keycap press machines operate quietly and efficiently. Robotic arms accurately pick and place keycaps, control systems monitor every press-fitting parameter, and quality inspection systems ensure product quality.

These automated equipment not only improve production efficiency but also, through unparalleled precision and consistency, ensure every keyboard leaving the factory meets the highest standards. With continuous technological progress, Hengcang’s automatic keycap press machine will continue to lead the keyboard manufacturing industry toward greater intelligence and efficiency.