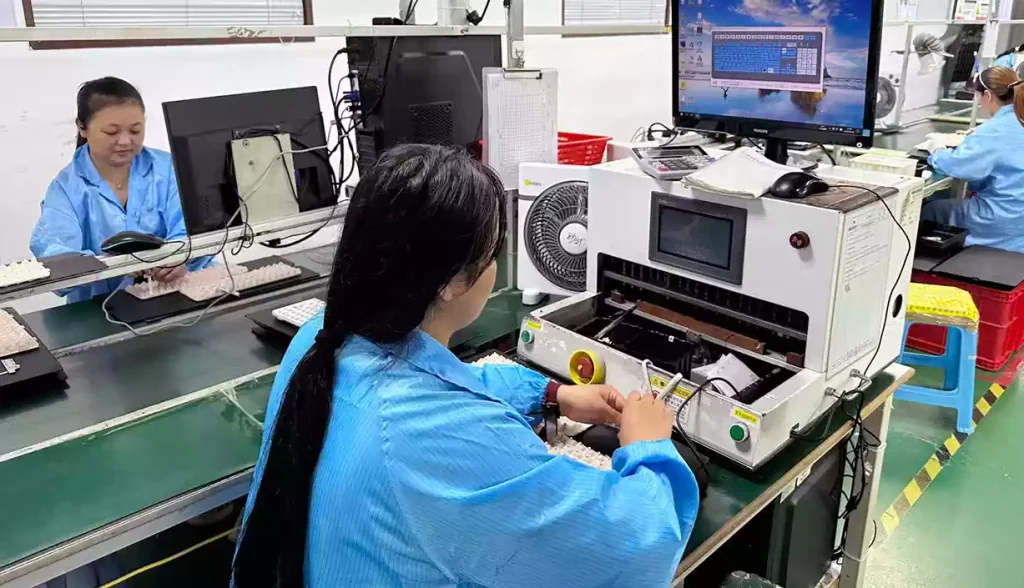

In the cleanroom of Hengcang Electronic Technology, testers conduct key function tests on a batch of semi-finished keyboards. They complete over 5,000 key press tests daily, ensuring every key responds accurately.

Keyboard testers are core executors of Hengcang’s quality control system. They are deployed at key nodes throughout the production process—from semi-finished product testing to finished product inspection—building a solid defense for keyboard quality. Through strict testing processes, Hengcang Electronic Technology controls the defect rate of keyboard products to below 0.1%.

This article delves into the work of Hengcang’s keyboard testers, covering everything from semi-finished product testing to finished product inspection, fully demonstrating how this role ensures the outstanding quality of keyboard products.

01 Role Positioning & Core Value of Keyboard Testers

Keyboard testers play the critical role of "quality gatekeepers" at Hengcang Electronic Technology. They need sharp observation skills and professional testing expertise to accurately identify product defects, ensuring outgoing keyboards meet the highest quality standards.

The core value of testers lies in defect prevention rather than just defect identification. By conducting early tests on semi-finished products, they detect and resolve issues in the early stages of production, preventing problems from flowing into subsequent processes and significantly reducing quality costs.

Hengcang Electronic Technology divides testers into two specialized roles: semi-finished product testers and finished product testers. Semi-finished product testers focus on verifying the functionality of components such as circuit boards and key switches, while finished product testers perform comprehensive inspections on fully assembled keyboards. This specialized division makes testing more detailed and efficient.

As keyboard technology continues to evolve, the role of testers is also advancing. They are no longer just simple inspectors but cross-functional talents who need to master electronic knowledge, testing principles, and equipment operation. Hengcang provides continuous training for testers to ensure they keep up with technological developments.

02 Semi-Finished Product Testing: Early Quality Control in Keyboard Manufacturing

Semi-finished product testing is the first line of defense for keyboard quality. It focuses on testing individual keyboard components to ensure each part meets quality requirements before assembly.

Circuit Board Testing

Circuit board testing is a key link in semi-finished product testing. Testers use professional equipment to check if the PCB (Printed Circuit Board) has correct circuit connections and if there are any short circuits or open circuits. They also test the board’s electrical performance to ensure impedance matching meets design requirements.

Key Switch Testing

Key switch testing focuses on evaluating mechanical performance. Testers conduct random sampling for key switch durability testing: using automated equipment to press switches at a frequency of 1–2 presses per second to assess their lifespan. According to industry standards, high-quality mechanical key switches should withstand over 50 million presses.

Keycap Testing

Keycap testing includes material inspection, dimension measurement, and print quality evaluation. Testers check for defects such as burrs or deformation on keycaps, ensuring uniform keycap thickness and clear, durable character printing. Hengcang Electronic Technology applies strict keycap inspection standards: requiring character offset to be less than 2 degrees and position deviation from the center to be no more than 0.3mm.

Connectivity Testing

Connectivity testing targets wireless keyboard modules. Testers verify the stability of Bluetooth or 2.4G connections, testing signal strength and data transmission accuracy under different environments and distances to ensure reliable wireless connectivity.

Semi-finished product testing also includes component compatibility verification—ensuring components from different suppliers work perfectly together. Testers record test data to provide a basis for subsequent quality improvements.

03 Finished Product Testing: Comprehensive Inspection Before Keyboard Shipment

Finished product testing is the final quality checkpoint for keyboards. Testers conduct all-round inspections on fully assembled keyboards to ensure products meet shipment standards.

Visual Inspection

Visual inspection is the first step in finished product testing. Testers carefully check for scratches or dents on the keyboard case, verify keycap alignment, and ensure character printing is clear. They also inspect keyboard labels and packaging to confirm compliance with customer requirements.

Functional Testing

Functional testing is the core of finished product testing. Testers connect the keyboard to a computer and use professional testing software to check the function of each key. They ensure all keys trigger normally without failure or repeated triggering. Special function keys (such as multimedia keys and backlight adjustment keys) are also key test focuses.

Performance Testing

Performance testing evaluates the keyboard’s response speed and stability. Testers conduct high-speed typing tests to check for input lag. For gaming keyboards, they also test the N-key rollover function—ensuring all keys are accurately recognized when pressed simultaneously.

Tactile Consistency Testing

Tactile consistency testing relies on testers’ professional experience. They check if the pressing feel of all keys is consistent, and if there are issues such as stuck keys or poor rebound. For mechanical keyboards, key noise is also an evaluation indicator, ensuring it stays within an acceptable range.