As a professional mechanical keyboard manufacturer and China mechanical keyboard manufacturer, HengCang-Tech has always regarded quality control as the core of its production system. For keyboard OEM and ODM services, intermediate quality control (IQC) during production is the key link to ensure product consistency, reliability and meet customer customization requirements. This article will elaborate on the intermediate quality control system of HengCang-Tech's keyboard production, demonstrating how we, as a trusted mechanical keyboard factory, mechanical keyboard supplier and mechanical keyboard OEM manufacturer, realize strict quality control in the production process.

Incoming Raw Material Inspection: The Foundation of Intermediate Quality Control for Mechanical Keyboard OEM Production

The intermediate quality control of keyboard production starts with the strict inspection of incoming raw materials. As a professional mechanical keyboard ODM manufacturer, HengCang-Tech clearly knows that the quality of raw materials directly determines the final product performance. For all incoming materials such as mechanical keyboard shafts, keycaps, PCBs, and cables, we have established a multi-dimensional inspection standard.

Our quality inspection team uses professional testing equipment to conduct full inspections on the raw materials provided by suppliers. For example, the mechanical shaft, the core component of the keyboard, will be tested for trigger force, stroke, and service life to ensure that it meets the production requirements of gaming mechanical keyboard manufacturer. For PCBs, we focus on testing circuit conductivity and anti-interference performance to avoid short circuits or signal loss during use. Only raw materials that pass the inspection can enter the next production link, laying a solid foundation for subsequent intermediate quality control.

Semi-Finished Product Testing: Key Link of Intermediate Quality Control in Mechanical Keyboard Factory

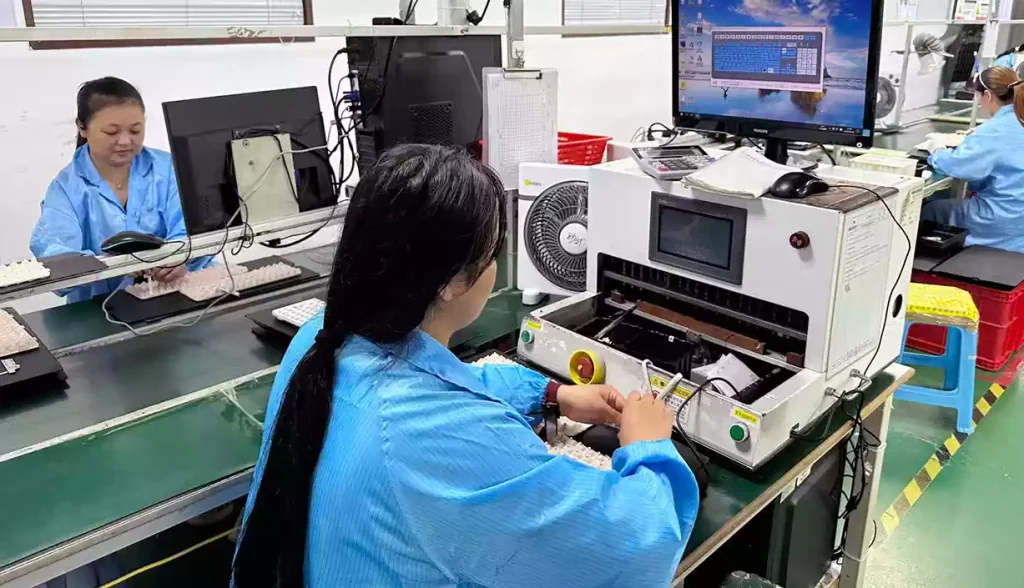

In the process of keyboard assembly, semi-finished product testing is a crucial intermediate quality control link. HengCang-Tech has set up multiple inspection nodes in the assembly process to conduct real-time testing of semi-finished products, ensuring that quality problems are discovered and solved in a timely manner before entering the next process.

When the keyboard completes the initial assembly of shaft bodies and keycaps, our inspectors will conduct a comprehensive test on each semi-finished product. This includes testing the trigger sensitivity of each key, ensuring that there is no stuck or ineffective key; detecting the fit between the keycap and the shaft body to ensure smooth key pressing and rebound. For gaming mechanical keyboards, we also conduct preliminary testing on the keyboard's response speed, which is an important indicator for gaming mechanical keyboard manufacturer. In addition, for semi-finished products such as assembled PCBs with electronic components, we use professional testing instruments to check the soldering quality and component operation status, avoiding quality hazards caused by poor soldering or faulty components.

Core Component Performance Verification: Guarantee for High-Quality Mechanical Keyboard ODM Services

As a mechanical keyboard maker focusing on high-quality products, HengCang-Tech attaches great importance to the performance verification of core components in the intermediate quality control stage. The core components such as mechanical shafts, RGB backlight modules, and control chips directly affect the user experience of the keyboard. Therefore, we have established a dedicated core component performance testing laboratory.

In the intermediate stage, we conduct accelerated life tests on mechanical shafts, simulating long-term use scenarios to ensure that the service life of the shafts meets the industry's high standards. For RGB backlight modules, we test parameters such as light uniformity, color accuracy, and brightness adjustment sensitivity to ensure that the backlight effect meets the customization requirements of customers. For control chips, we verify functions such as signal transmission speed and compatibility with different operating systems, ensuring that the keyboard can work stably in various usage environments. This strict core component performance verification enables HengCang-Tech to provide reliable mechanical keyboard OEM service and ODM solutions for global customers.

Real-Time Process Monitoring: A Key Measure for China Mechanical Keyboard Manufacturer to Ensure Quality Stability

To ensure the stability of product quality during mass production, HengCang-Tech has introduced an intelligent real-time process monitoring system in the intermediate production stage. As a large-scale mechanical keyboard factory and mechanical keyboard supplier, we realize that manual inspection alone is difficult to cover all production details, so intelligent monitoring has become an important supplement to intermediate quality control.

The system monitors key parameters in the production process in real time, such as temperature, humidity, and assembly torque during soldering. Once an abnormal parameter is found, the system will immediately issue an alarm and stop the relevant production line, preventing unqualified products from being produced in batches. At the same time, the system records all production data, which provides a reliable basis for subsequent quality traceability and process optimization. This combination of manual inspection and intelligent monitoring ensures that every link of intermediate quality control is in place, and effectively improves the pass rate of products.

Intermediate Quality Control Documentation and Traceability: The Basis for Standardized Mechanical Keyboard OEM/ODM Services

Standardized documentation and complete traceability are important parts of HengCang-Tech's intermediate quality control system. As a professional mechanical keyboard OEM manufacturer and mechanical keyboard ODM manufacturer, we know that perfect documentation is not only conducive to internal quality management, but also an important guarantee for meeting the quality requirements of global customers.

In the intermediate quality control process, every inspection result, test data and process parameter is recorded in detail. Each semi-finished product is assigned a unique traceability code, which can trace back to the batch of raw materials, the production line, the operator and the inspection personnel. This traceability system not only enables us to quickly locate and solve quality problems when they occur, but also enhances customers' trust in our products. For customers who need keyboard OEM services, this standardized documentation and traceability system can also meet their strict quality audit requirements.

In conclusion, intermediate quality control is the core competitiveness of HengCang-Tech as a professional China mechanical keyboard manufacturer, mechanical keyboard factory and mechanical keyboard supplier. Through strict incoming raw material inspection, comprehensive semi-finished product testing, professional core component performance verification, intelligent real-time process monitoring and standardized documentation traceability, we ensure the stability and reliability of each keyboard product. In the future, HengCang-Tech will continue to optimize its intermediate quality control system, provide higher quality mechanical keyboard OEM and ODM solutions for global customers, and consolidate its position as a trusted gaming mechanical keyboard manufacturer and mechanical keyboard OEM service provider.

Our core products (mechanical & commercial keyboards) enjoy strong sales in key overseas markets of North America, Europe and Southeast Asia. Backed by solid market performance, we are the designated manufacturer/core supplier for leading domestic and international clients, including China’s top GRG Banking Group, Guangzhou Zhongqi, Zhuhai Xuesi Tech (DURGOD); Korean partners WAYCOS & MSTONE (core mechanical keyboard suppliers for Korea’s consumer electronics market); and global gaming/office keyboard brands Lofree, DIERYA and Piping.