As a professional keyboard manufacturer, HengCang Technology integrates mature process technology and meticulous quality control into its production process. Below is an intuitive overview of the core process framework for keyboard production:

Design & R&D --> Mold Manufacturing --> Injection Molding/Stamping Forming --> Printing & Surface Treatment --> Automated Assembly --> Tactile Feel Tuning --> Quality Inspection --> Packaging & Shipping

🔧 Exploring Core Production Links

Several key links in this process directly determine the final quality of the keyboard.

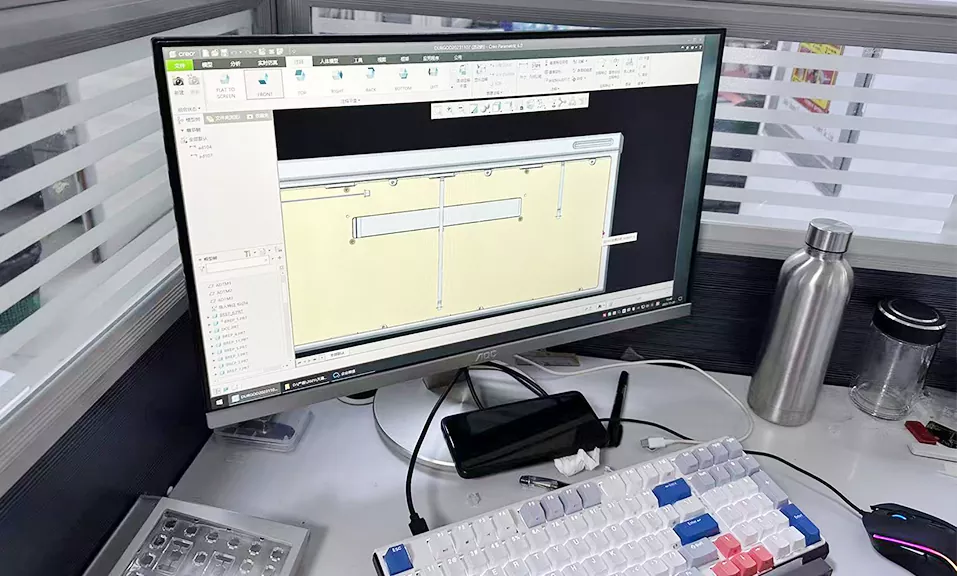

HengCang-Tech has a dedicated design team capable of conducting product design according to customer requirements. After the design plan is finalized, precision mold design and manufacturing are carried out. The precision of the mold directly affects the dimensional accuracy and surface quality of components such as keyboard casings and keycaps.

Core components of the keyboard, such as casings and keycaps, are mainly produced through the injection molding process, for structural parts like metal mounting plates, stamping, and other processing methods are adopted. These processes ensure the structural strength of the components.

In the assembly phase, HengCang-Tech uses specialized equipment. Examples include automatic switch inserting machines, automatic keycap pressing machines, automatic screw driving machines, and AOI inspection systems. This reduces manual intervention and guarantees product consistency and cleanliness, reflecting the company’s efforts in improving production automation.

HengCang-Tech emphasizes that it is "the first manufacturer in the industry to achieve batch tactile feel tuning." This means it possesses the technology for standardized and batch testing and fine-tuning of keyboard tactile feel, ensuring that keyboards from the same batch or even different batches can deliver a stable and consistent tactile experience. This is a key advantage that sets it apart from many peers.

💎 Summary

Overall, HengCang-Tech’s keyboard manufacturing process is an interconnected system. From design and development, mold manufacturing, component production, and automated assembly to the critical tactile feel tuning and final testing, every link reflects its emphasis on quality control, production efficiency, and tactile consistency.

We hope the above information helps you understand HengCang-Tech’s keyboard manufacturing process. If you have more in-depth questions about a specific link — such as the manufacturing of keycaps with specific materials — HengCang-Tech is pleased to provide additional details.