For foreign trade buyers, securing a reliable keyboard OEM manufacturer is the core prerequisite for ensuring product quality, controlling costs, and achieving on-time delivery. However, the current keyboard manufacturing market is a mixed landscape where small workshops coexist with formal factories. A moment of inattention could lead to problems such as shoddy goods passed off as quality products, delivery delays, and lack of after-sales support.

Drawing on 12 years of in-depth experience in the keyboard OEM industry, this article summarizes 5 practical tips to steer clear of pitfalls. These tips will help you quickly identify high-quality keyboard OEM manufacturers that meet your needs and mitigate procurement risks.

I. Key to Avoiding Pitfalls: Verify a Manufacturer’s Actual Strength First and Reject Shell Factories

Many buyers are easily lured by low quotes, yet they overlook verifying whether the manufacturer has genuine production capabilities. In the end, they fall into the trap of shell factories—businesses that subcontract orders to small workshops after winning them, leaving product quality and delivery times completely unguaranteed.

The right approach requires three key verification steps:

1.1 Conduct On-site Inspections or Video Factory Audits

Reputable keyboard OEM manufacturers will take the initiative to cooperate with factory audits. Focus your inspection on the following critical points: whether the manufacturer has independent production workshops, injection molding equipment, SMT assembly lines, general assembly production lines and quality inspection zones; whether production workers wear uniform employee IDs; and whether operating procedures are standardized. If a manufacturer refuses an audit on the grounds of “confidentiality” or “tight production capacity”, there is most likely something amiss.

1.2 Review Production Qualifications and Case Studies

Request the manufacturer to provide its business license (the scope of business must include “keyboard manufacturing”), ISO 9001 quality management system certification, and records of past foreign trade collaborations (such as order documents for exports to the EU and the US). High-quality manufacturers will also take the initiative to showcase customer feedback and product test reports to prove their industry reputation.

1.3 Verify Production Capacity Compatibility

Here’s a no-brainer tip for picking a keyboard OEM: check if their production capacity lines up with your order size—and then some. If you need 100k units a month, don’t settle for a factory that only does 100k. Look for one that cranks out 200k+ each month. That extra headroom is your safety net—you won’t get stuck waiting for delayed shipments if something goes sideways with their production. And trust me, always ask for their production reports from the last three months. It’s the easiest way to tell if their capacity numbers are real, not just empty marketing talk.

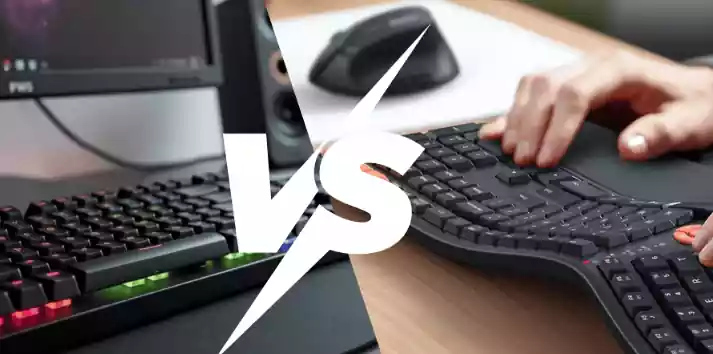

II. Clarify Product Specifications: Lock in Details in Advance to Avoid Rework Later

Ambiguous specifications are a major cause of disputes in keyboard OEM collaborations. If a buyer only says “we need a mechanical keyboard” without defining specific parameters, the manufacturer may substitute low-grade components, resulting in products that fail to meet expectations.

Core specifications that need to be clarified in advance are as follows:

Core Bits You Can’t Mess UpKeycaps: pick PBT or ABS (don’t waste time on cheap stuff). Switches: Cherry MX is solid, or go for reliable domestic brands—your call. Circuit boards? FR-4 fiberglass is the only way to go—trust me, it’s worth it.

Functionality Must-HavesDoes it have RGB? Full-key rollover (gaming folks will flip if this is missing)? Macro programming? And don’t forget wireless—Bluetooth or 2.4G, whichever fits your clients’ needs.

Looks & Branding StuffLock in the exact size, the color you want (not “similar” colors—exact), and how your logo goes on—screen print or laser engrave, no vague terms.

Quality Rules That Can’t Be BrokenMechanical switches: 50 million keystrokes minimum. Membrane: 10 million at least. Also, it needs to resist splashes and pass hot/cold tests—otherwise, you’ll be dealing with returns left and right.

The Most Important Move EverWrite every single one of these details down, make the factory sign it, and stick it in your contract. This stops them from weaseling out later with “we didn’t agree to that”—saves you so much headache.

III. Review the OEM Production Process: Manufacturers with Standardized Processes Ensure More Controllable Quality

Top-tier keyboard OEM factories don’t just make keyboards—they’ve got rock-solid production processes locked in. Every step, from initial demand talks and prototyping, to mass production and final delivery, comes with crystal-clear standards and hard timeline checkpoints you can track. Small workshops, though? Their workflows are all over the place. More often than not, you’ll get a decent prototype—only to end up with mass-produced goods that fall way short of the mark.

Focus on these 3 key process milestones:

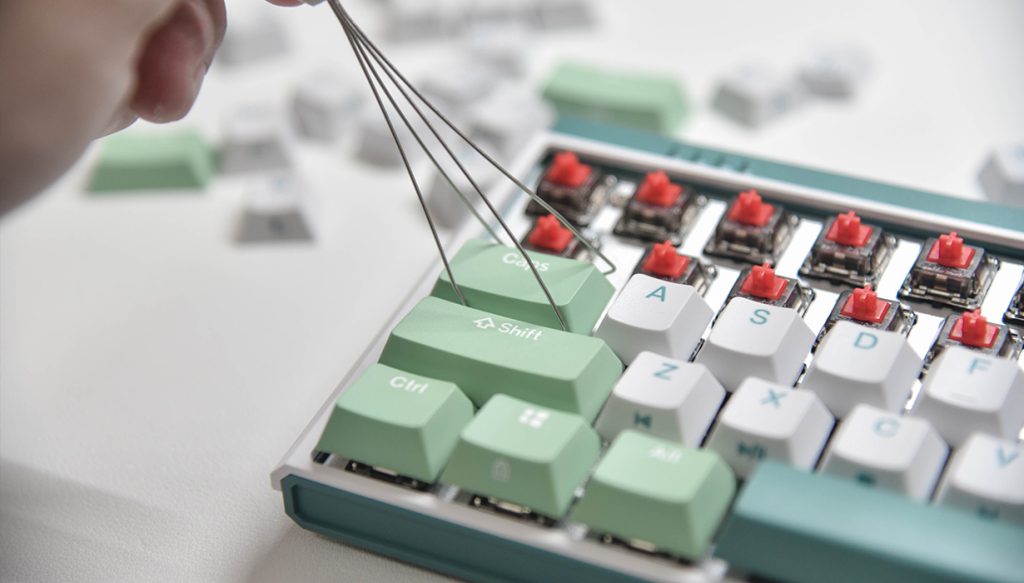

3.1 Prototyping Phase

Solid, trustworthy manufacturers will always run prototyping standards by you first—before they even start making samples. Prototyping usually takes 7–10 days, and every sample they send should have a test report—stuff like key sensitivity, backlight uniformity, all the basics covered. Don’t skip asking them to ship the samples to you; hold the sample, test it out yourself. Make sure the key feel and functions line up with what you’re after before you greenlight mass production.

3.2 Mass Production Quality Inspection

Find out about the manufacturer’s quality inspection process: whether it implements 100% inspection (testing every single unit) or random sampling inspection (testing products in a set ratio); whether it has dedicated quality inspectors; and whether the inspection items cover key functions, surface defects, and packaging integrity. Top-tier manufacturers will allow buyers to station quality inspectors at the factory, or provide photos/videos of quality checks during mass production.

3.3 Delivery Lead Time and Logistics

Here’s a non-negotiable step when working with a keyboard OEM: don’t leave delivery details vague. Lock in the mass production lead time first—for example, how many days they need for 100k units. Then clarify delivery: are you picking up the goods, or is the factory handling shipment? And don’t forget to ask about their logistics partner—do they have foreign trade experience? Can they ship straight to your target market? Oh, and one more thing: always add a late delivery compensation clause to the contract. This way, they can’t delay shipments arbitrarily—keeps them accountable, and you won’t get stuck waiting around.

IV. Verify Certifications and Compliance: Avoid Foreign Trade Customs Clearance Risks

Let’s be clear—when sourcing keyboards for foreign trade, your products have to meet the certification standards of your target market. No exceptions. If they don’t, you could end up with shipments held up at customs, or even have your goods seized outright. This isn’t just a box-ticking exercise—it’s a make-or-break check when picking a keyboard OEM.

Core certification requirements for different markets:

EU Exports

You’ve got to have CE certification (that’s the European safety compliance mark) and RoHS certification (restricts hazardous substances in products)—both are non-negotiable, no ifs, ands, or buts about it.

US Exports

FCC certification is a must—this covers the Federal Communications Commission’s electromagnetic compatibility standards; don’t skip it.

Japan Exports

PSE certification (for electrical appliance and material product safety) is non-negotiable if you’re shipping to Japan.

Global Universal Certifications

Environmental certifications and ISO 9001 quality management system certifications are the go-to credentials that hold weight no matter where you’re selling.

Here’s a non-negotiable move to avoid getting scammed during procurement: demand original certification documents from the factory—don’t let them fob you off with photocopies. Then go to the issuing body’s official site and verify those certification numbers. This is the only way to keep factories from using forged certs to pass off their substandard junk as qualified goods.

V. Lock in MOQ & After-Sales Agreements: Slash Procurement Costs, Guarantee Post-Purchase Support

In B2B procurement, MOQ requirements and after-sales service have a direct, tangible impact on both your bottom-line procurement costs and the quality of your post-partnership experience. It’s essential to hash out every last detail with your manufacturing supplier early on.

5.1 MOQ and Quotation

MOQ can vary a ton from one keyboard OEM supplier to another. For standard mechanical keyboards, MOQs usually land between 1,000 and 5,000 units.

You can always negotiate on this—all it comes down to is your order size. Place a big bulk order, and you can ask for a per-unit discount. If you’re just starting small with your initial purchase? Check if the supplier does small-batch trial runs—500 units, for instance—to keep your trial-and-error costs low.

5.2 After-Sales Service

Make sure you nail down the after-sales stuff first. If the keyboards have quality issues—like keys jamming up or not registering, or scratches/dents on the casing—ask the factory straight up if they’ll do returns or replacements. Then figure out who handles the whole return/replacement process, and who’s picking up the tab for all that. Don’t forget to ask if they’ll throw in any tech help—like user guides or tips for fixing small problems. The really good factories will offer a one-year warranty, and swap out any defective units for free. That way, you won’t be stuck high and dry if something goes wrong.

Conclusion: Choosing the Right Keyboard OEM Manufacturer Is Half the Battle Won

When sourcing keyboards for foreign trade, there’s no need to blindly chase low prices. Instead, you should screen manufacturers around the five core pillars: genuine strength, clear specifications, standardized processes, complete certifications, and reliable after-sales support. It is advisable to prioritize reputable factories with over 10 years of industry experience and a wealth of foreign trade track records. Investing more time in verification upfront will save you a great deal of hassle down the line.

Need a trustworthy keyboard OEM manufacturer? We’re your go-to choice. We hold all essential production certifications: ISO 9001, CE, RoHS and FCC. With a monthly output of over 200,000 units, we handle OEM orders for every keyboard type—mechanical, membrane, wireless, and more. We also cater to small-batch trial orders and offer fully customized solutions for your unique requirements.

[Call to Action] Click to inquire now and get the following for free: ① Factory live-action videos ② Product samples ③ Detailed quotation sheets. Our professional team will provide one-on-one answers to all your procurement questions!