The OEM manufacturing process of HengCang-Tech for Lofree keyboards closely aligns with the brand’s pursuit of unique aesthetics and personalized tactile feel, forming a system that integrates precision manufacturing and strict quality control.

1. Insertion Workshop: Keyboard Core Assembly

Production starts at the Insertion Workshop, with the core task of assembling key switches, mounting plates, gasket foam, switch pads, and other components into a keyboard core.

- Automated Key Switch Insertion: The workshop uses automatic insertion machines to precisely insert key switches into the holes of the mounting plate. This automated equipment can greatly improve production efficiency and ensure insertion accuracy, with the defect rate controlled at an extremely low level.

- Keyboard Core Assembly: After the installation of key switches, we proceed to the keyboard core assembly stage. Assemble the switch pads, gasket foam, and the mounting plate with inserted key switches together, followed by semi-finished product testing.

2. Processing Workshop: Refinement of Appearance and Basic Structure

The Processing Workshop is mainly responsible for the processing and preliminary assembly of keyboard casings and other structural components, which are related to the product’s first impression and basic tactile feel.

- Upper and Lower Case Appearance Inspection: Casing components (such as upper case and lower case) undergo strict visual inspection. The inspection is usually carried out under specific conditions: the lighting is 40W twin-tube fluorescent lamps, the angle between the inspector’s eyes and the product is 0-45 degrees, and the distance is 45-60 centimeters. The standards are extremely detailed, with clear upper limits on the number and size of allowable minor scratches or defects.

- Footrest and Rubber Feet Installation: Install the footrest at the corresponding positions on the keyboard, attach the footrest pads, and stick the rubber feet to the bottom case.

3. Assembly Main Line: Finished Product Formation and Function Verification

After all components are ready, the keyboard enters the final assembly and testing line.

- Finished Product Assembly: In the finished product assembly stage, automated equipment is widely used.

- Finished Product Testing: The assembled keyboard must undergo comprehensive functional and performance tests. The tests usually include:

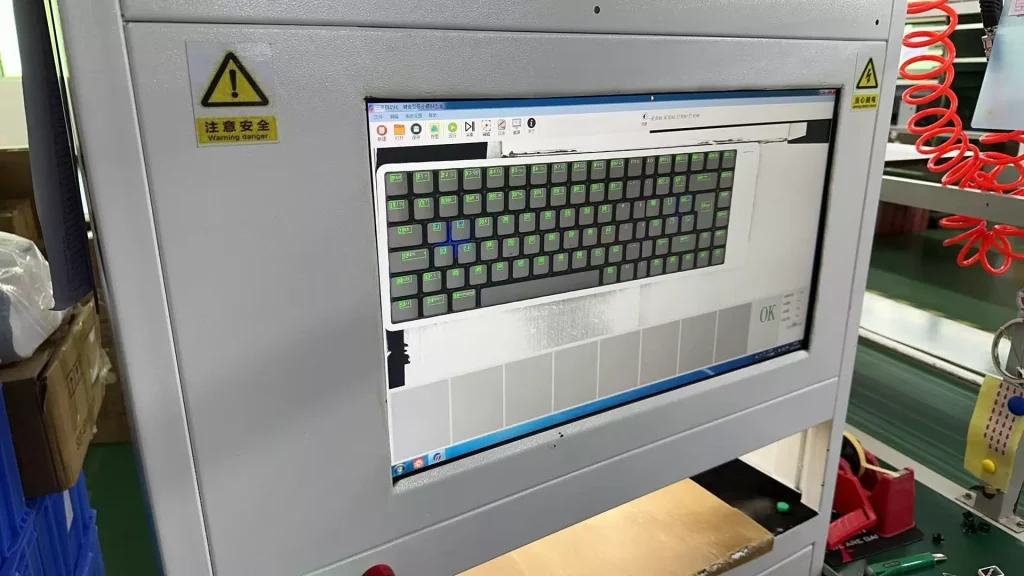

- Functional Test: Connect the keyboard to a computer and use professional testing software to check whether all functions are normal, including the actuation of each key, the stability of multiple connection modes (such as wired, Bluetooth, 2.4G), and backlighting.

- Tactile Feel and Durability Test: Detect the key pull-out force, bounce time, key pressure, etc., and conduct a special life test to simulate long-term use, ensuring that the keys meet the standard of millions of presses.

- Visual Inspection: Use visual inspection devices to automatically check the printing quality of the characters on the keycaps, ensuring no misprinting, missing printing, and clear characters.

4. Packaging and Delivery: Final Protection and Quality Commitment

Keyboards that have passed all tests enter the final packaging stage.

- Labeling and Protection: The packaging line prints and pastes traceable barcodes based on the information of each keyboard. The equipment also automatically places protective foam to prevent scratches on the product's appearance during transportation.

- Special Packaging Materials:For accessories such as keyboard bags, high-density EVA material may be used. It is produced through processes such as laser cutting, hot pressing molding, and surface flocking with velvet fabric, providing comprehensive protection for the keyboard.

5. Summary

In summary, HengCang-Tech’s OEM manufacturing for Lofree keyboards is an interconnected and strictly controlled precision manufacturing process. It starts with precision component installation in the Insertion Workshop, goes through detailed refinement of appearance and basic structure in the Processing Workshop, then completes finished product integration and rigorous functional verification on the Assembly Main Line, and finally ensures the product reaches users intact through a modern packaging process.

We hope the above explanation helps you gain a more specific understanding of the various links in keyboard OEM manufacturing. If you have a deeper interest in a specific process, we can continue to discuss it.