We specialize in providing high-quality OEM & ODM Keyboard solutions tailored to your needs.

In the computer peripherals industry, we focus on three core businesses: mechanical keyboard OEM/ODM, professional keyboard R&D, and ergonomic office peripheral customization. Guided by the corporate spirit of "Pursue Excellence, Never Settle," we keep forging ahead with continuous innovation: whether optimizing mechanical switch tactile feedback, enhancing switch sensor precision, or improving the stability and uniformity of keyboard RGB backlighting, we consistently adhere to self-upgrading. This enables us to solidify the long-term competitiveness of our core peripheral business and fully empower your OEM/ODM projects, strengthening their market competitiveness.

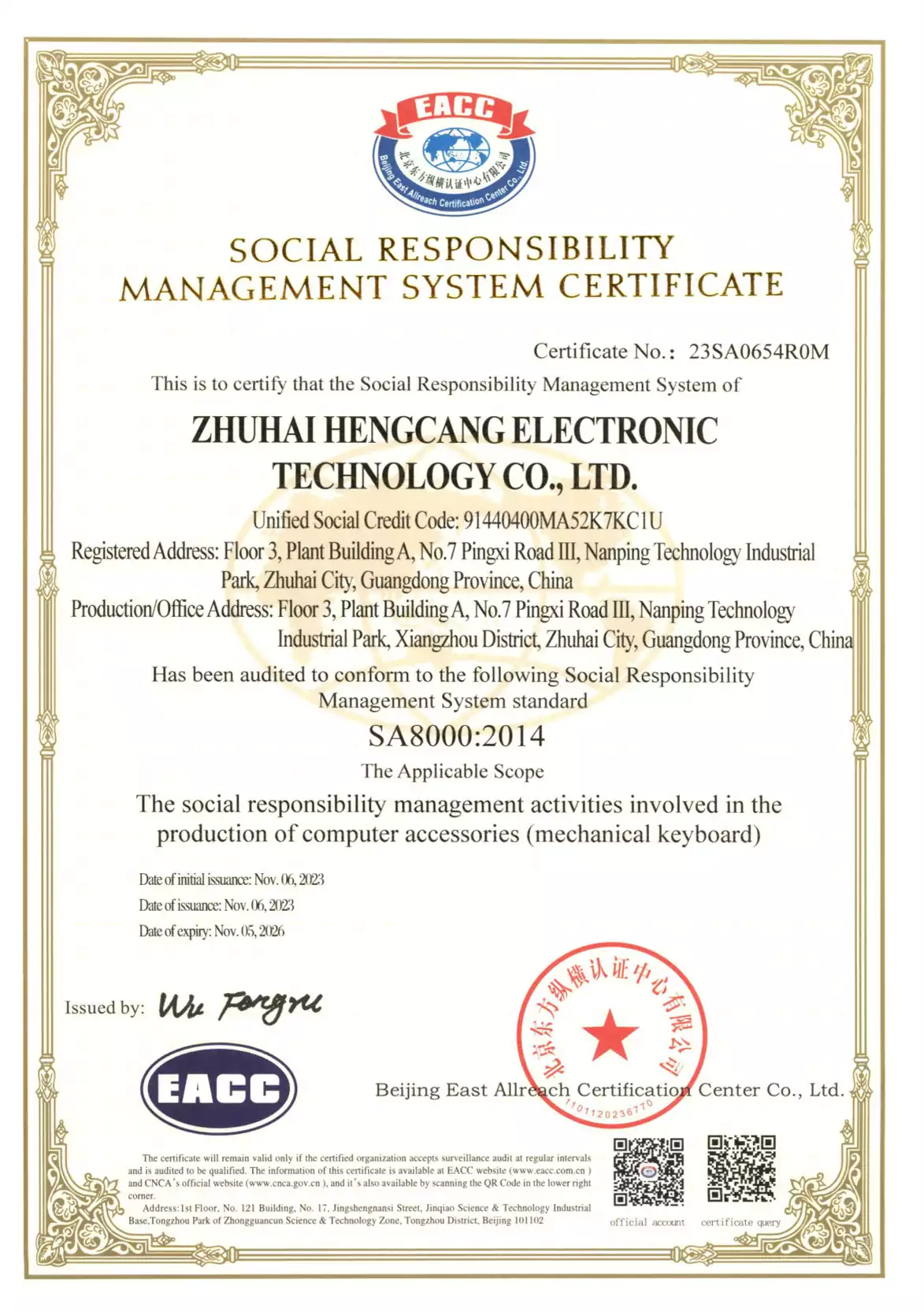

Taking quality as the core cornerstone of survival and development, we strictly comply with the ISO 9001 quality management system and conduct rigorous multiple rounds of performance and reliability testing on finished computer peripherals. Built on this solid foundation, we are committed to deepening the innovative development of the computer peripherals business, fully guaranteeing the quality, stability, and core market competitiveness of your OEM/ODM projects. We look forward to partnering with you to create a brilliant future in the peripherals industry.

Your information will be kept strictly confidential.

“We will earn your trust with professionalism, quality, and sincerity. My team and I would be pleased to meet with you (either in person or via video call) to learn about your business, needs, and expectations. Please let us know a time that works for you.”