You want your e-sports mechanical keyboard to work well every time. Today’s factories have strong quality-control systems that are integral to the keyboard assembly production process. These systems help ensure that each keyboard is consistent in quality. Special labs check every keyboard for strength and performance. Zhuhai Hengcang Electronic Technology Co., Ltd. is a top company because it embraces innovative ideas. Workers meticulously check the keyboard at each step of the assembly process, ensuring you receive a keyboard that meets high standards.

Key Takeaways

- Quality control makes sure each keyboard is made well. Factories use strong tests to find problems early.

- Automation helps factories work faster and make fewer mistakes. Machines test and put together keyboards. This keeps quality the same for each one.

- Workers get regular training to help stop mistakes. Trained workers spot problems fast. This helps make better keyboards.

- Factories follow rules like ROHS and REACH. These rules keep keyboards safe and help the environment. Following rules is important for good quality.

- Factories always try to get better. They listen to what customers say. They change how they work to make keyboards even better.

Quality Control Overview

Key Strategies

You want your keyboard to work well every time. Factories use different ways to make sure you get a good product. Workers look at keyboards to find problems early. They check parts and packaging so broken ones do not reach you. They test some keyboards and make sure they work before sending them out.

Factories follow rules like ISO 9001. This rule helps companies make better products. It cares about making customers happy and uses steps to improve. You get help from risk-based management, which finds and fixes problems fast. Factories always try to make products better by improving all the time.

Here is a table with some main ways top factories work:

| Strategy | Description |

|---|---|

| Training | Training helps workers make fewer mistakes and do their jobs well. |

| Quality Management System (QMS) | A QMS helps factories track and fix problems over time. |

| Communication | Talking between engineers and workers helps things run smoothly and lowers mistakes. |

Statistical process control (SPC) is important too. Control charts help watch how things are made and how well they work. Factories use real-time data to see changes and patterns. Workers can fix problems right away to keep products good.

Automation in Factories

Automation helps make keyboards faster and more exact. Machines do testing and building, so there are fewer mistakes. Automated systems use AI to find broken parts and wrong pieces quickly. You get fast feedback, so workers can fix things right away.

Automated SPC systems give instant feedback and use test rules the same way every time. This lowers mistakes and keeps quality high. Automation means more good keyboards and less waste. You get keyboards that always meet tough standards.

Tip: Automation makes keyboards faster to build and helps every keyboard be just as good as the others.

Keyboard Assembly Production Process

You want your keyboard to work well every time. The assembly process has many steps. Each step helps make sure your keyboard is good and reliable.

Design and Prototyping

First, engineers plan the keyboard. They make a blueprint. They think about how it looks and feels. They also think about how it works. After planning, they build a sample keyboard. This is called a prototype. The prototype helps find mistakes. Some mistakes are not testing all features. Others are caring too much about looks. Sometimes, safety rules are missed. These problems must be fixed before moving on.

Here are the main steps in making a keyboard:

- Designing the Keyboard

- Prototyping

- Material Selection

- Switch Assembly

- Circuit Board Production

- Assembly and Testing

- Quality Assurance and Packaging

Tip: Good design and testing help stop big mistakes later.

Material Inspection

You need to check all parts before using them. Zhuhai Hengcang Electronic Technology Co., Ltd. uses a special lab and an IQC system. This system checks every batch of switches and boards. It also checks other parts. You make sure parts follow strict rules like ROHS and REACH. These rules keep bad chemicals out and protect nature.

- The IQC system helps you:

- Make sure raw parts are good.

- Stop delays by finding problems early.

- Save money by catching bad parts before making keyboards.

- Follow rules and avoid recalls.

- Protect the product by checking important things.

You also test parts in the lab. You check if they are safe and have no smell. If you find a problem, you fix it fast. This keeps the factory working well.

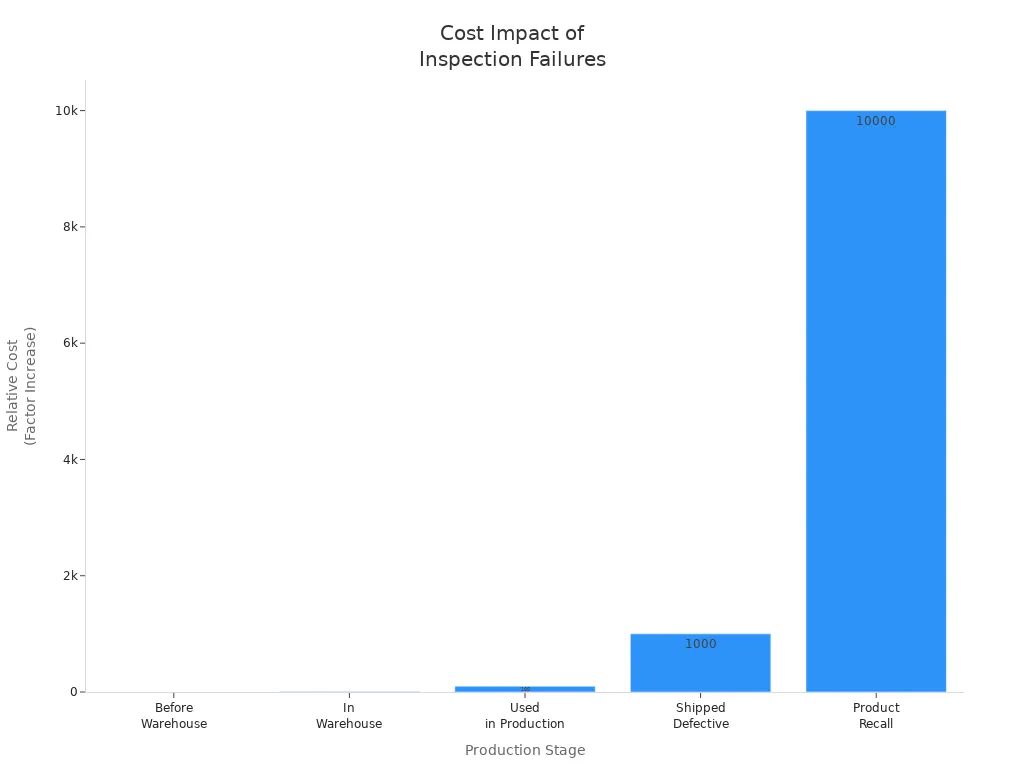

| Stage | Description | Cost Implications |

|---|---|---|

| 1 | Before it Enters the Warehouse | Saves money and work, stops waste. |

| 2 | Enters the Warehouse But is not Yet Used | Costs can be much higher if problems are found late. |

| 3 | Used in Production | Costs go up more because of fixing and extra work. |

| 4 | Product is Shipped with Defective Materials | Needs deep checks and fixes, costs a lot more. |

| 5 | Product Recall | Costs get very high, hurts reputation, and may need to pay fines. |

Note: Checking early saves money and keeps your company trusted.

Assembly Line Checks

Next, you go to the assembly line. Workers and machines put together switches, boards, and keycaps. You use checks to find problems before shipping.

| Testing Method | Advantages | Disadvantages |

|---|---|---|

| Visual Inspection | Easy, does not damage parts, finds big problems | Can miss small issues, needs more tools sometimes |

| PCBA SMT First Article Inspection | Fixes mistakes before making many keyboards, finds design problems | Takes time, stops the line for checking |

| In-Circuit Testing | Checks whole circuit, faster than testing each part | Only finds simple problems, needs special tools |

| Flying Probe Testing | Fast and trustworthy | May miss hard-to-find problems |

Machines test every part. They look for electrical problems. They make sure every key works. You also follow safety rules. ROHS and REACH tests keep keyboards safe and green.

Final Testing

Last, you do final tests. Every keyboard gets checked before shipping.

- Electrical Testing: You make sure wires work and there are no shorts.

- Visual Inspections: You look for bad solder or broken parts.

- Functional Testing: You check special keys and USB ports.

- Environmental Testing: You see how the keyboard works in hot or wet places.

Zhuhai Hengcang Electronic Technology Co., Ltd. uses top machines for these tests. You get a keyboard that is safe and works well.

Callout: Final tests make sure your keyboard is ready for games, work, and daily use.

You can trust Zhuhai Hengcang’s process to give you a safe and strong keyboard every time.

Challenges and Solutions

Material Variability

Building keyboards comes with many problems. One big problem is material variability. Sometimes, the quality or price of raw materials changes. You also have to follow rules about electronic waste. It can be hard to get parts on time if the supply chain has issues.

- Supply chain problems can slow down shipments.

- Changing material prices can hurt your budget.

- You need to follow rules for throwing away electronic waste.

To fix these problems, you use smart plans. You pick suppliers you can trust and test every batch of materials. You keep suppliers close to your factory so you get parts faster. Here is a table that shows how top companies deal with material variability:

| Strategy | Description |

|---|---|

| Material Sourcing Strategy | Find good suppliers with fair prices and use strong networks for steady supply. |

| Quality Control and Testing | Check quality carefully to make sure keyboards meet world standards before shipping. |

| Proximity to Suppliers | Being near suppliers in China helps you get parts faster and makes buying easier. |

Scaling Production

You want to make more keyboards but keep them good. You use quality switches, USB controllers, and steady power for RGB lights. You test sample keyboards for heat and switch strength. You look at old data to see if the process works well. You read reports from suppliers about problems.

- Ask for sample keyboards to test until they break.

- Check old process data for important details.

- Look at reports about problems and broken parts.

You also use standard PCB sizes and common parts. You start with firmware that already works. You use 2-layer PCBs when you can. You begin with small batches, like 200-500 keyboards, to test the market. This helps you lower risk and make the assembly process better.

Continuous Improvement

You always try to make keyboards better. You listen to what customers want and set goals for quality. You look at each step to find weak spots. You use root cause analysis to fix problems. You watch the process with special tools and try new ideas.

| Key Tools and Concepts | Description |

|---|---|

| Voice of the Customer | Learn what customers want so the product matches their needs. |

| Critical to Quality (CTQ) | Set important goals for product quality. |

| Process mapping | Find weak spots in the making process. |

| Root cause analysis | Use methods like 5 Whys to find out why problems happen. |

| Statistical process control (SPC) | Watch the process to make sure it stays good. |

| Design of experiments (DOE) | Test new ideas to make the product better. |

- Leaders help with quality.

- Workers join training and quality groups.

- You take steps to stop problems before they start.

- You check on suppliers.

- You measure how happy customers are and use their feedback.

Tip: Always improving helps you make fewer mistakes and keeps customers happy.

Impact on Reliability

Product Performance

You want your keyboard to last a long time and work every day. Modern factories use strong quality control to make sure you get a reliable product. You see this in the way they measure performance. Here are some important metrics that show how well your keyboard works:

| Metric | Description |

|---|---|

| Defect Rates | Counts how many keyboards have problems during production. Lower numbers mean better quality. |

| First-Pass Yield Statistics | Shows how many keyboards pass all tests the first time. High numbers mean the process works well. |

| Long-Term Reliability Testing | Tests keyboards with heat, pressure, and time to see how long they last. |

You get a keyboard that passes tough tests. Factories use machines to press keys thousands of times. They check if the switches still work after heavy use. You benefit from these tests because your keyboard stays strong and responsive. Brands like Cherry MX, Razer, and Ducky use strict testing. Their keyboards last longer and perform better. Zhuhai Hengcang Electronic Technology Co., Ltd. follows these high standards. You receive a keyboard that meets your needs for gaming and work.

Tip: Reliable keyboards help you win games and finish work faster.

Customer Satisfaction

You care about how your keyboard feels and works. Quality control makes sure you get a product that feels good every time you use it. You notice smooth key presses and fast response. You enjoy a keyboard that does not break easily.

- You get fewer problems and returns.

- You trust the brand because your keyboard works well.

- You feel happy when your keyboard matches your needs.

Factories listen to your feedback. They use your ideas to make keyboards better. You see new features and better designs each year. Zhuhai Hengcang Electronic Technology Co., Ltd. works with partners and customers to improve satisfaction. You get support if you have questions or issues.

Note: A reliable keyboard gives you confidence. You can focus on your game or your work without worry.

You can see that strong quality control helps every e-sports mechanical keyboard. Careful testing and set steps make sure you get keyboards you can trust. Zhuhai Hengcang Electronic Technology Co., Ltd. uses top labs and cares about the environment. You get good products because they always try their best. New ideas will soon change how keyboards are made:

| Innovation Type | Description |

|---|---|

| Artificial Intelligence (AI) | AI spots patterns and makes quality control better right away. |

| Robotics-Based Automation | Robots check keyboards faster and with more care. |

You will get even better keyboards as these new tools improve.

FAQ

How does Zhuhai Hengcang Electronic Technology Co., Ltd. test keyboard quality?

Every keyboard gets tested in a modern lab. Experts check the key switches and circuit boards. They also look at how the keyboard works overall. Special machines measure how hard you press keys and how long they last. They also test if keyboards work in different places. This helps you get e-sports mechanical keyboards you can trust.

Why is ROHS and REACH compliance important for keyboards?

You want your keyboard to be safe. ROHS and REACH rules keep bad chemicals out of keyboards. These rules help protect your health and nature. Zhuhai Hengcang Electronic Technology Co., Ltd. follows these rules for every keyboard they make.

What makes e-sports mechanical keyboards different from regular keyboards?

E-sports mechanical keyboards respond faster and last longer. They use special switches and strong materials. This helps you play games or work for a long time. Zhuhai Hengcang Electronic Technology Co., Ltd. makes these keyboards for top performance.

How do factories prevent defects in keyboard production?

Factories use strict quality control steps. Workers and machines check every part before putting keyboards together. Automated systems find problems early. Staff get regular training to spot issues fast. This helps lower defects and makes keyboards more reliable.

Can you trust the reliability of Zhuhai Hengcang keyboards?

You can trust these keyboards to last. Every keyboard goes through tough tests for strength and performance. The company uses advanced labs and strict checks. You get a keyboard that is ready for gaming or work.