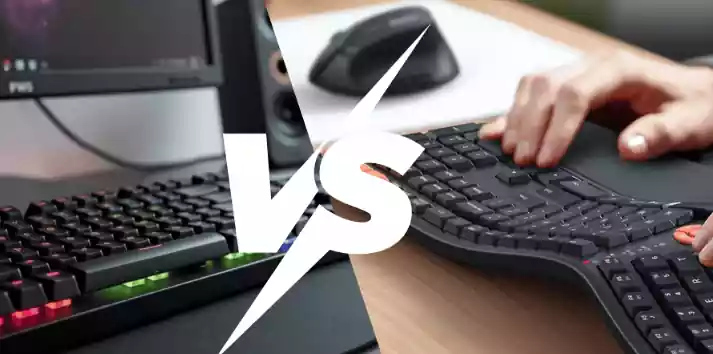

In the fiercely competitive keyboard industry, product quality and delivery stability are the cornerstones of an enterprise’s foothold. Whether it is gaming keyboards, office keyboards or customized ones, a professional production process is the key to ensuring product consistency and durability.

As a manufacturer deeply rooted in the keyboard manufacturing sector, we boast full-chain production capabilities covering everything from product R&D and mold development to mass production and quality inspection. By implementing refined management and control over every single step, we deliver high-quality keyboard production solutions to our clients. Professional Keyboard Manufacturer

I. Core Stages of Keyboard Production: Full-Process Control from R&D & Prototyping to Mass Production & Quality Inspection

Keyboard production is a systematic project. Oversights in any single stage can compromise the quality of the final products. Traditional workshop-style production often suffers from non-standardized processes and lack of strict controls, which leads to low product yield rates and unstable performance. In contrast, legitimate keyboard manufacturers establish standardized production systems. They set clear technical standards and acceptance criteria for every stage—from the initial R&D and prototyping, to the intermediate injection molding, SMT placement, assembly and debugging, and then to the final full inspection, packaging and delivery. This ensures that every batch of products delivered to customers meets the expected standards.

1.1 R&D & Prototyping: The Front-End Core for Precisely Meeting Customer Requirements

R&D and prototyping mark the starting point of keyboard production, and directly determine whether the products align with market demands. Professional keyboard manufacturers assign senior engineers to communicate with customers, and conduct an in-depth breakdown of requirements—including product positioning (gaming/office/industrial use), core parameters (switch type, connection method, functional features), and appearance design (dimensions, color, keycap style). Afterwards, they complete product design via 3D modeling and produce handboard samples for customer confirmation.

After sample confirmation, the manufacturer will conduct small-batch trial production to test the product’s structural stability, key press feel and functional integrity, optimizing and adjusting the product based on test data to ensure product consistency during the mass production phase. Keyboard R&D and Prototyping Service

1.2 Injection Molding: The Quality Foundation of Keyboard Casings and Keycaps

Injection molding is the primary production process for core keyboard components (casings and keycaps), and its process capability directly impacts the product’s texture and durability. Legitimate manufacturers adopt high-precision injection molds and select premium raw materials (such as ABS, PBT, and aluminum alloy). By implementing precise control over injection temperature, pressure and duration, they prevent issues like casing deformation, keycap burrs and sink marks.

Taking the production of PBT keycaps as an example, manufacturers will strictly screen the purity of raw materials, adopt two-shot injection molding technology to ensure clear and wear-resistant characters, and control the uniformity of keycap thickness at the same time to guarantee consistency in key press feel in subsequent processes. For the aluminum alloy casings of high-end keyboards, additional surface treatment processes such as anodization and sandblasting will be applied to enhance texture and oxidation resistance.

1.3 SMT Placement and Circuit Debugging: Ensuring Stable Keyboard Performance

The circuit system is the neural hub of a keyboard, and the SMT placement and circuit debugging stage directly affects the keyboard’s response speed and stability. Professional manufacturers employ automated SMT placement equipment to precisely solder electronic components such as resistors, capacitors and chips onto the PCB circuit board. Compared with manual soldering, this method not only improves efficiency significantly, but also greatly reduces the likelihood of cold soldering and mis-soldering.

After the completion of SMT placement, the process moves on to the circuit debugging phase. Engineers use professional equipment to test the on-off status of the circuit and signal transmission speed for each key, and troubleshoot issues such as short circuits and open circuits. For wireless keyboards, additional tests are conducted on core performance metrics including the stability of Bluetooth/2.4G connections and battery life, ensuring that the circuit system of every single product complies with technical standards. Keyboard SMT Placement Industry Standards

1.4 Assembly, Debugging and Full Inspection: The Last Line of Defense for Quality

In the assembly and debugging phase, workers accurately assemble components including keycaps, switches, PCB circuit boards and casings in accordance with standardized procedures. They then conduct key feel debugging—by adjusting switch tightness and keycap fit to ensure consistent actuation force and travel distance for every single key. For keyboards with RGB backlighting, the uniformity of the backlight is also calibrated to prevent issues such as brightness inconsistency and light leakage.

After assembly is completed, the process moves on to the full inspection and quality control phase, where legitimate manufacturers adopt an approach combining 100% inspection and random sampling: they conduct a comprehensive check on every single product for its appearance (free from scratches and defects), key functionality (normal actuation of each key) and connectivity (stable wired and wireless connection), while conducting random sampling inspections in a specified proportion to test such aspects of the products as durability (e.g., key lifespan testing) and environmental adaptability (e.g., high-low temperature and humidity testing). Keyboard Quality Inspection Standards

All qualified products will undergo cleaning and anti-static packaging before being transferred to the finished goods warehouse for delivery. For foreign trade orders, additional export compliance testing will be conducted in accordance with the requirements of the target markets to ensure that the products meet international certification standards such as CE, RoHS and FCC. Keyboard Export International Certification Requirements

II. Core Advantages of Legitimate Keyboard Manufacturers: Dual Guarantee of Quality and Delivery

Compared with workshop-style production, the core advantages of legitimate keyboard manufacturers are reflected in three aspects: first, a standardized production system, which ensures consistent product quality through full-process control, with the product yield rate reaching over 99%; second, professional R&D capabilities, which enable quick responses to customers' customized needs and shorten the cycle from design to mass production; third, comprehensive after-sales support, which includes providing free replacements for defective products generated during the production process and offering technical support services to customers.

This flexibility has made HengCang Tech the designated gaming keyboard factory for household names like DURGOD, Lofree, DIERYA, and WAYCOS (a core supplier for Korea’s consumer electronics market). It’s also a trusted partner for GRG Banking Group and Zhuhai Xuesi Tech, proving that its expertise extends beyond gaming to commercial and terminal keyboards—all built with the same precision that gamers demand.

For B2B purchasers, choosing a legitimate manufacturer not only reduces procurement risks, but also secures more flexible cooperation plans—such as supporting small-batch trial orders, providing OEM/ODM manufacturing services, and assisting in completing export certifications—helping customers quickly seize market opportunities.

III. How to Choose a Reliable Keyboard Manufacturer? Focus on These 3 Key Points

When choosing a reliable keyboard manufacturer, you need to focus on three key aspects: first, verify the production strength by prioritizing manufacturers with owned production workshops and complete production lines, and you can confirm their equipment configuration and production scale through on-site inspections or video factory audits; in addition, check the qualifications and cases by requesting manufacturers to provide business licenses, ISO9001 quality management system certification and past cooperation cases, especially OEM records with well-known brands, while also being able to inquire about the products’ international certification certificates; finally, clarify the cooperation details, including defining the MOQ (Minimum Order Quantity), mass production lead time, pricing system and after-sales policy, so as to avoid cooperation disputes in the later stage. Keyboard OEM/ODM Cooperation Inquiry

Summary: Professional Production Processes, Building High-Quality Keyboards

From R&D and prototyping to mass production and delivery, refined control over every stage is the core strength of legitimate keyboard manufacturers in creating high-quality products. Whether it is gaming keyboards, office keyboards or customized keyboards, only by relying on standardized production systems, professional technical teams and strict quality inspection processes can manufacturers meet the market’s high requirements for quality and performance.

If you are looking for a reliable keyboard manufacturer, we have comprehensive end-to-end production capabilities. From customized R&D to batch production, and from quality control to export services, we will provide full-process support for you. Consult now to get a free customized plan and quotation!