Hengcang SMT·PCBA | Core Service Provider for Computer Peripheral Electronics Manufacturing

- Specialized in SMT Assembly and PCBA Manufacturing

- Over 20 years of focus on PCBA SMT assembly for computer peripherals—providing end-to-end SMT delivery for computer peripherals!

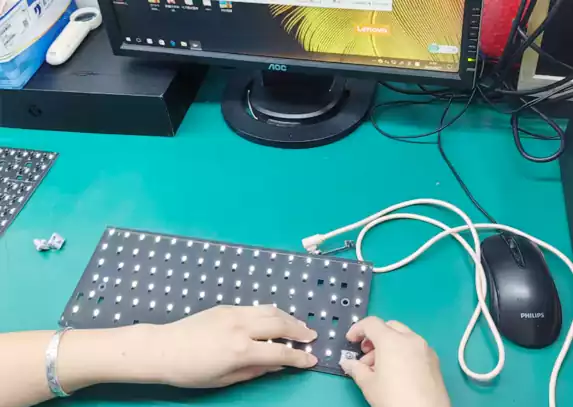

20 Years in Mechanical Keyboards / E-Sports Peripherals | One-Stop SMT, Assembly & Testing Solutions for Small-Batch Trials & Large-Scale Production

We specialize in providing high-quality OEM & ODM Keyboard solutions tailored to your needs.

A national high-tech enterprise specialized in SMT assembly and PCBA manufacturing.

Providing high-reliability PCBA solutions for consumer electronics & automotive electronics & industrial control, boasting a 99.9%+ yield rate while cutting customers' mass production cycles by 30%.

What is a One-Stop PCBA Solution?

Before officially launching our one-stop PCBA service, we first clarify the core definition of "PCBA"—it is a general term for "PCB manufacturing, component placement, and finished product assembly." The "one-stop" PCBA model refers to end-to-end service ranging from "customer requirement communication" to "finished product delivery and after-sales service," eliminating the hassle of customers coordinating with multiple suppliers. It truly realizes the closed-loop service of "requirement submission → solution implementation → finished product delivery," solving the pain points of customers such as "multi-party communication, cumbersome processes, and fragmented responsibilities."

With "precision manufacturing + flexible PCBA services" as our core advantage, we turn every PCBA into a reliable cornerstone for customers' electronic products.

Our Philosophy

Why Choose Us?

- Our company owns advanced imported SMT equipment specialized in computer peripheral production (focused on mechanical keyboards), including:

- High-speed Yamaha SMT placement machines (YS12, YS24) and medium-speed models—ideal for efficient assembly of peripheral PCBs (e.g., mechanical keyboard mainboards, gaming mouse control boards);

- Screen printers for precise peripheral PCB circuit printing;

- Reflow ovens for stable soldering of electronic components (e.g., keyboard chip modules, mouse sensor parts);

- AOI (Automatic Optical Inspection) machines for strict PCBA quality checks (e.g., mechanical keyboard PCB solder joint detection, gaming headphone motherboard defect screening).

- With standardized SOPs (Standard Operating Procedures) for computer peripheral PCBA SMT processes, Our company is fully capable of delivering SMT placement and testing for PCBA boards of various computer peripherals—ensuring accuracy and stability of core peripheral components.

- ISO9001:2015 (General Manufacturing Quality Management System) – ensures stable quality throughout the entire SMT/PCBA process

- IATF16949:2016 (Automotive Electronics-Specific Certification) – meets strict automotive-grade reliability and durability requirements

- ISO13485:2016 (Medical Electronics-Specific Certification) – complies with rigorous cleanliness and traceability standards for medical device PCBs

- RoHS 2.0/REACH – adheres to EU environmental regulations, restricting the use of hazardous substances in electronic components

We provide end-to-end electronic manufacturing OEM services for computer peripheral customers, covering "PCB design support (e.g., mechanical keyboard PCB layout optimization), component sourcing (including core parts such as Cherry MX switches for mechanical keyboards and sensors for game mice), SMT placement production (for peripheral PCBA boards), finished product inspection, assembly (e.g., mechanical keyboard keycap installation), and packaging with a strong emphasis on Keyboard OEM & ODM capabilities."

PCBA assembly equipment

We offer flexible cooperation models for startup clients

A one-stop computer peripheral OEM/ODM manufacturing service provider, offering full-process PCB design, SMT placement, assembly, and packaging—helping clients reduce mechanical keyboard manufacturing costs by 10%.

We have mature electronic component supplier networks (covering passive components, IC chips, and connectors), ensuring we can secure competitive, high-quality quotes for components in customers' BOM lists. Additionally, we can offer alternative electronic component solutions that meet performance standards to help cut costs and shorten production lead times.

Our SMT lines deliver efficient, accurate SMT placement (Surface Mount Technology) and DIP insertion (Dual In-line Package), monitor production via MES (Manufacturing Execution System), support real-time data collection, analysis & integration, and offer three-proof coating (anti-moisture, anti-corrosion, anti-mildew) for PCBA — all to meet diverse PCBA needs.

We are capable of conducting targeted electrical performance testing, aging testing, and reliability testing for PCBA products strictly in accordance with customer-customized specifications. We also provide professional assistance to customers with respect to a full range of product certifications like CE, FCC, and RoHS.

We can assist customers with laser engraving (for computer peripheral parts like mechanical keyboard casings), structural component assembly (e.g., PCB bracket installation), and finished product assembly. By integrating these multi-link manufacturing support, we streamline their computer peripheral management processes and reduce overall product costs in peripheral production.