You start the mechanical keyboard manufacturing process by focusing on several key stages. First, you create the design with CAD software such as Fusion 360 or SolidWorks. Next, you build a prototype, often developing the PCB with components like the ATmega32u4. Then, you coordinate with factories for the case and circuit board. Zhuhai Hengcang Electronics Technology Co., Ltd. uses this approach, placing great value on blueprint design, prototyping, and injection molding at the beginning.

Key Takeaways

- Start with a solid design. Use CAD software to create a blueprint that reflects your ergonomic needs and typing habits.

- Choose the right materials. Select plastics like ABS or PBT for keycaps based on desired texture and durability.

- Test prototypes thoroughly. Ensure comfort and functionality by testing each design before mass production.

- Prioritize quality control. Conduct inspections and tests to catch defects early and maintain high standards.

- Embrace customization. Personalize your keyboard with unique layouts, materials, and lighting to match your style.

Design and Blueprint

Layout Planning

You begin the mechanical keyboard manufacturing process by focusing on layout planning. This step shapes the user experience and determines how comfortable and efficient your keyboard feels.

- Ergonomic design matters because it helps you avoid strain and discomfort during long typing sessions.

- Key switch types influence how each keystroke feels and sounds, so you should consider your preferences for tactile feedback and noise.

- Layout variations, such as full-size, tenkeyless, or compact, let you choose a keyboard that matches your typing habits and workspace needs.

- The physical arrangement of keys should match your daily routines, making typing faster and more accurate.

Tip: Try different layouts and switch types before finalizing your blueprint. You will discover what fits your hands and workflow best.

Prototyping

Once you finish layout planning, you move to prototyping. You create a digital blueprint using CAD software, such as Fusion 360 or SolidWorks. This blueprint guides the next steps and helps you visualize the final product. You build a prototype, often starting with a custom PCB that supports your chosen layout and switch type. You test the prototype for comfort, durability, and functionality. You adjust the design based on feedback and testing results. This stage ensures your keyboard meets your expectations before mass production begins.

Mechanical keyboard manufacturing relies on careful design and prototyping. You set the foundation for quality and customization by refining every detail at this stage.

Mechanical Keyboard Manufacturing Process

Zhuhai Hengcang Electronics Technology Co., Ltd. has specialized in mechanical computer keyboard production for 25 years. You benefit from their expertise at every stage of mechanical keyboard manufacturing. Let’s explore each step in detail.

Injection Molding

You start with injection molding, which forms the backbone of mechanical keyboard manufacturing. You inject molten plastic into a mold to create the keyboard base and other components. This process ensures precision and consistency. The most common plastics include ABS, PBT, and polycarbonate. Each material offers unique characteristics for durability and feel.

| Plastic Type | Application | Characteristics |

|---|---|---|

| ABS | Keycaps | Vibrant colors, smooth texture |

| PBT | Keycaps | Textured, resilient, matte finish |

| Polycarbonate | Keyboard bases | Transparent, strong, lightweight |

You complete each injection molding cycle for a keyboard case in about 5 seconds. This speed allows you to produce large quantities efficiently.

| Average Cycle Time | Value |

|---|---|

| Injection Molding Time for Keyboard Case | 5.0 seconds |

Tip: Choose your plastic type based on the desired texture and durability for your keyboard.

Switch Production

You select and install switches, which define the typing experience. Mechanical keyboard manufacturing often uses Gateron switches. You can choose from several types, each with a different actuation force:

- Gateron Red: 45g

- Gateron Black: 50g

- Gateron Green: 80g

- Gateron Clears: lightweight, lower force requirement

- Gateron Browns: middle-of-the-road option, suitable for average users

You match switch types to your preferences for tactile feedback and sound.

Plate and PCB

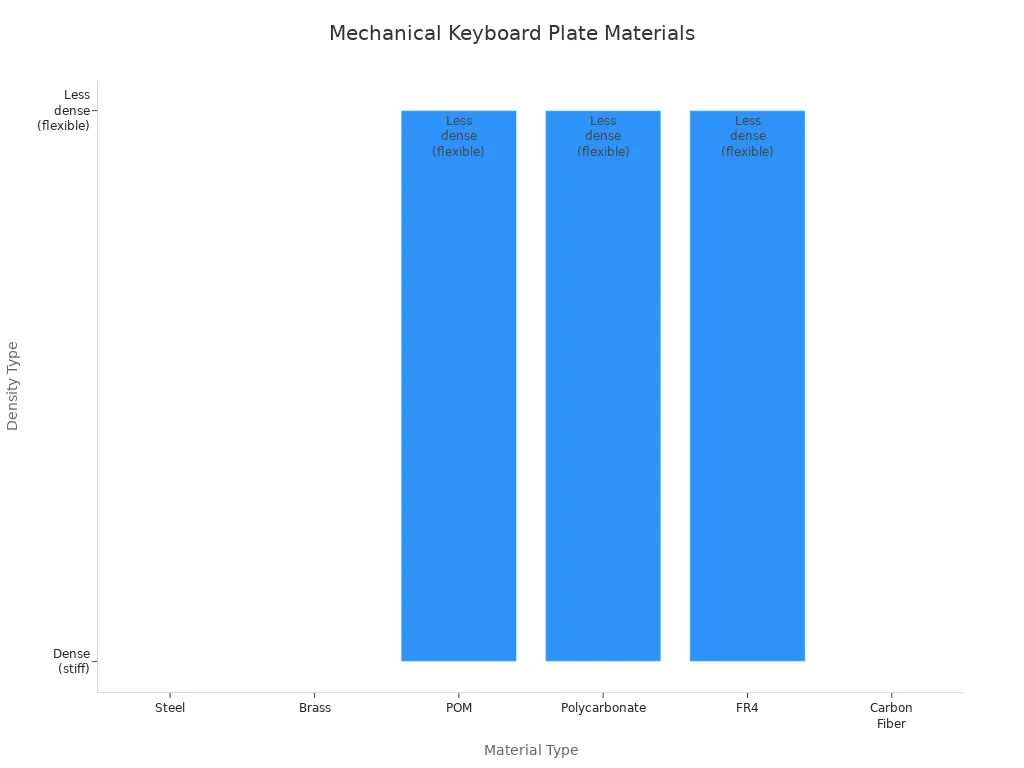

You need a sturdy plate and a reliable PCB to support the switches and electronics. Mechanical keyboard manufacturing uses various plate materials, each affecting durability and sound.

| Material Type | Density Type | Typing Experience Description | Sound Profile Description |

|---|---|---|---|

| Steel | Dense (stiff) | Stiffer typing, no flex, harsher bottom out | Resonates, higher pitch |

| Brass | Dense (stiff) | Solid feel, nice with tactile switches | Higher pitch |

| POM | Less dense | Deeper sound, less harsh bottom-out | Thocky sound |

| Polycarbonate | Less dense | Nice flex, pleasant typing | Thocky sound |

| FR4 | Less dense | Neutral sound, good flex | Neutral sound |

| Carbon Fiber | Dense (stiff) | Stiffest among less dense materials | Higher pitch |

You use FR4 for most PCBs because it resists moisture and heat, provides excellent insulation, and ensures long-term durability. Standard PCB thickness ranges from 1.2mm to 1.6mm, which balances strength and flexibility.

Case and Keycap Creation

You create the case and keycaps using materials that match your needs. ABS and PBT are the most common choices. ABS feels smooth and lightweight, while PBT offers superior durability and a textured finish. POM is less common but provides a unique feel.

- ABS: Common in budget keyboards, lightweight, smooth

- PBT: Premium, durable, textured

- POM: High-performance, soft yet resilient

You also decide how to produce keycap legends. Double-shot molding creates legends that never fade, while pad printing may wear off over time.

| Keycap Legend Method | Durability | Description |

|---|---|---|

| Double-shot molding | Most durable | Legends merge with keycap material, never fade |

| Pad printing | Susceptible | Legends can fade, printed as a surface layer |

Assembly

You assemble all components to complete the keyboard. You mount the switches onto the plate and PCB, secure the case, and attach the keycaps. You connect the electronics and test each function. Zhuhai Hengcang Electronics Technology Co., Ltd. uses strict assembly protocols to ensure every keyboard meets high standards.

Note: Careful assembly prevents defects and ensures a satisfying typing experience.

Mechanical keyboard manufacturing combines precision, material science, and skilled assembly. You control each step to create a keyboard that matches your expectations for quality and performance.

Quality Control

Inspection

You play a vital role in ensuring every keyboard meets strict quality standards. Inspection begins after assembly. You check each unit for visible flaws and functional issues. Common problems include unresponsive key presses, sticky or repeating keys, noisy operation, connectivity issues, lighting problems, and random disconnects. You identify these defects early to prevent faulty products from reaching customers.

Tip: Early detection of defects saves time and reduces costs.

You follow international standards during inspection. These standards help you maintain consistent quality and safety in mechanical keyboard manufacturing. Here is a table showing the most frequently applied standards:

| Standard | Description |

|---|---|

| ISO9001 | Quality management system standard ensuring consistent quality in production. |

| ROHS | Restricts hazardous substances in electrical and electronic equipment. |

| REACH | Regulation concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals. |

| CE | Conformity marking indicating compliance with health, safety, and environmental protection standards. |

| FCC | Federal Communications Commission standards for electronic devices. |

You use these standards to guide your inspection process and guarantee product reliability.

Testing

You test each keyboard to confirm durability and performance. Testing covers several areas. You start with a visual inspection to check for physical damage. You perform a typing test to evaluate tactile feedback. You run a rollover test to ensure multiple keys register at once. You assess switch durability by pressing each key thousands of times. You measure noise levels to meet user preferences. You check customization features and confirm compatibility with different systems. You also assess ergonomics for comfort during long use.

Here is a list of common tests you perform:

- Visual Inspection: Check for physical damage or defects.

- Typing Test: Evaluate tactile feedback and typing experience.

- Rollover Test: Ensure multiple keys register simultaneously.

- Switch Durability Test: Assess the consistency and responsiveness of switches.

- Noise Level Test: Measure the keyboard's sound output.

- Customization Test: Evaluate programmable features and ease of use.

- Compatibility Test: Check recognition and functionality with systems.

- Ergonomics Test: Assess comfort and support during extended use.

You have specialized in the production of mechanical computer keyboards for 25 years. Your experience helps you refine inspection and testing methods, ensuring every keyboard meets high standards in mechanical keyboard manufacturing.

Customization

Layouts

You can choose from a wide range of keyboard layouts to match your typing style and workspace. Full-size layouts offer every key, including a number pad, which helps with data entry. Tenkeyless layouts remove the number pad, saving space and making your desk less crowded. Compact layouts, such as 60% or 65%, focus on portability and minimalism. You select a layout based on your daily needs. Gamers often prefer smaller layouts for faster mouse movement. Writers and programmers may want more keys for shortcuts.

Tip: Try different layouts before you decide. Your comfort and efficiency depend on the right choice.

Materials

You have many options when selecting materials for your custom mechanical keyboard. Each material changes the feel and sound of your keyboard. Here are some popular choices:

- PC (Polycarbonate): Soft, flexible, and looks great with RGB lighting.

- Aluminum: Sturdy, crisp typing feel, and bright sound.

- FR4: Balanced, moderate flexibility, and muted sound.

- POM (Polyoxymethylene): Cushioned, creamy sound, ideal for linear switches.

- Brass: Dense, warm sound, adds weight and a premium touch.

- Carbon fiber: Lightweight, bouncy feel, mid-range sound.

- Steel: Extremely rigid, sharp tone, and heavy.

The material you choose affects the acoustic properties of your keyboard. Rigid materials like aluminum and steel create a sharp, clicky sound. Softer materials such as plastic or wood absorb vibrations, resulting in a muted sound profile. The plate material also shapes the core switch sound. Stiffer plates enhance metallic tones, while flexible plates produce a warmer, smoother tone.

| Material | Sound Profile |

|---|---|

| Wood | Deeper, resonant |

| Aluminum | Cleaner, defined |

| Plastic | Muted, bass-heavy |

| Polycarbonate | Softer, gentle |

Personalization

You can personalize your keyboard in many ways. You select keycap colors, legends, and fonts to match your style. You add custom lighting effects for a unique look. You program macros and shortcuts to boost your productivity. You engrave your name or logo for a personal touch. Zhuhai Hengcang Electronics Technology Co., Ltd. has specialized in mechanical keyboard production for 25 years. Their experience helps you achieve the highest level of customization. You get a keyboard that fits your needs and expresses your personality.

Note: Personalization transforms your keyboard from a simple tool into a reflection of your identity.

You have seen that mechanical keyboard manufacturing involves many complex steps and skilled craftsmanship. Key factors include:

- Switch selection shapes your typing feel.

- Keycap variations change sound and comfort.

- Mounting styles affect the typing experience.

- PCB design adds technical challenges.

Customization gives you a keyboard that matches your needs and style. Manufacturers use advanced technologies, such as AI and IoT, to create unique products and follow market trends.

- Wireless technology for more freedom.

- Hot-swappable switches for easy changes.

- Compact, ergonomic designs for comfort.

- Eco-friendly materials for sustainability.

- AI-powered smart features.

Zhuhai Hengcang Electronics Technology Co., Ltd., with 25 years of experience, sets a strong example in quality control and customization.

FAQ

What materials work best for mechanical keyboard keycaps?

You can choose ABS, PBT, or POM. ABS feels smooth and light. PBT offers durability and a textured finish. POM gives a unique, soft touch.

Tip: PBT keycaps resist shine and wear over time.

How do you clean a mechanical keyboard?

You should unplug your keyboard first. Remove the keycaps with a keycap puller. Use a soft brush or compressed air to clean dust. Wipe the case with a damp cloth.

- For deep cleaning, wash keycaps with mild soap and water.

Can you customize the lighting on your keyboard?

Yes, you can. Many mechanical keyboards support RGB lighting. You can use software to change colors, patterns, and brightness. Some models let you save custom lighting profiles.

Note: Check your keyboard’s manual for specific instructions.

Why choose a manufacturer with 25 years of experience?

You get reliable quality and expert craftsmanship. A manufacturer with 25 years of experience, like Zhuhai Hengcang Electronics Technology Co., Ltd., understands every detail of the process.

| Benefit | Description |

|---|---|

| Quality | Consistent, high standards |

| Innovation | Latest technology used |

| Support | Strong after-sales service |