As the saying goes, "To do a good job, one must first sharpen one's tools." For mechanical keyboard enthusiasts, a keyboard with excellent feel and reliable quality is exactly that "sharp tool." But have you ever wondered: what processes does a seemingly simple mechanical keyboard go through, and what quality control measures are in place, before it finally reaches your hands? Today, let’s step into the world of mechanical keyboards and find out.

1. Design: The "Soul Blueprint" of a Mechanical Keyboard

The manufacturing of a mechanical keyboard starts with design. Like architects, designers draft initial sketches based on user needs, market trends, and technical feasibility. This stage defines critical elements such as the keyboard’s size, key layout, and color scheme. Imagine designers using professional CAD software to transform sketches into 3D models—essentially building a "keyboard structure" in the virtual world. Every detail of this structure directly impacts the keyboard’s future user experience.

For example, some designers create layouts with special function keys for gaming mechanical keyboard users, making in-game operations more intuitive. Others focus on ergonomic mechanical keyboards for office workers, designing compact, portable models that fit daily desk use. Just as cars come in different types to meet diverse needs, mechanical keyboards vary widely in design to cater to specific user groups.

2. Material Preparation: The Physical Foundation of a Mechanical Keyboard

Key materials for keyboard manufacturing include plastic, metal, and silicone. Plastic is used for the keyboard case and keycaps—acting like the keyboard’s "outer layer," it shapes the product’s appearance and touch. Metal enhances structural stability and durability, serving as the keyboard’s "skeleton" to ensure sturdiness. Silicone is used to make elastic pads under keys, ensuring a comfortable feel and proper rebound—like adding "springs" to the keyboard’s "joints."

Quality control during material preparation is crucial. Take plastic, for instance: different grades of plastic vary greatly in strength, toughness, and wear resistance. Low-quality plastic can lead to cracked or deformed cases, significantly shortening the keyboard’s lifespan. A well-known brand once had to recall keyboards because it used substandard plastic, resulting in widespread user complaints about easily damaged cases. Thus, selecting high-quality materials is the foundation of a reliable mechanical keyboard.

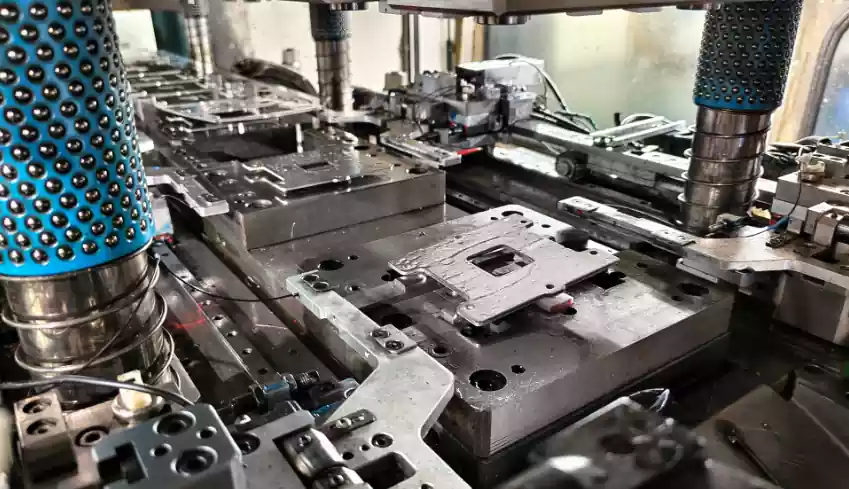

3. Mold Manufacturing: Precision Tools for Keyboard Production

After materials are prepared, molds for keyboard production are manufactured. Mold precision directly determines the quality of the final product—these molds are like "precision templates" that shape every detail of the keyboard. Mold manufacturing requires repeated polishing and adjustment to meet design standards.

In mold workshops, workers act like skilled craftsmen, using precision instruments to refine molds. Every dimension and angle is calibrated to the micrometer level. A keyboard manufacturer once faced issues where poor mold precision led to large gaps between keys. This not only hurt the keyboard’s appearance but also made it prone to dust buildup, affecting usability. The company eventually had to remake the molds, costing significant time and resources. This shows why mold manufacturing is a critical step in mechanical keyboard production.

4. Injection Molding: The "Birth" of Keyboard Components

Using the finished molds, plastic is heated to a molten state, injected into the molds, and cooled to form keyboard cases and keycaps. This process is like "transforming raw materials" into tangible keyboard parts. During injection molding, temperature and time must be strictly controlled: excessive heat can cause plastic degradation, while insufficient heat prevents full mold filling (leading to defects). Too long or too short cooling times also harm product quality.

For example, a factory once produced keyboard cases with bubbles and blemishes due to improper temperature control during injection molding. These defective products failed quality inspections and had to be discarded, resulting in substantial losses. Therefore, mastering injection molding techniques is vital to ensuring mechanical keyboard quality.

5. Assembly: Putting It All Together Like a Puzzle

After injection molding, components such as key switches, circuit boards, and cables are assembled into the keyboard case. The assembly process is like solving a puzzle—every part must be installed in the correct position. In assembly workshops, workers use specialized tools to combine parts with skill.

One critical step is switch installation—this is like fitting the keyboard’s "heart," as the switches under each key determine 70% of the keyboard’s feel. Common switch types include linear switches (e.g., red switches, silver switches) and tactile switches (e.g., blue switches, brown switches), each suited to different scenarios: linear switches are ideal for FPS game button-spamming, while tactile switches excel for typing. Even switches from the same batch may have a 5% variation in feel, so workers must be meticulous to ensure consistency across all keys.

A user once reported that certain keys on their keyboard felt different from others. An inspection revealed the issue: some switches were not installed properly during assembly. This highlights why no detail can be overlooked in the assembly process.

6. Testing: The Keyboard’s "Health Check"

After assembly, rigorous testing is conducted to ensure all functions work normally. This stage is like a "health check" for the keyboard, covering key sensitivity tests, key lifespan tests, and waterproof performance tests.

In key sensitivity tests, professional equipment measures the actuation force and travel of each key, ensuring accurate and responsive operation. Key lifespan tests simulate long-term use by repeatedly pressing keys—high-quality mechanical keyboards typically withstand over 50 million keystrokes. Waterproof tests involve submerging the keyboard in water (to a specified depth) to verify if it still functions.

A user once spilled water on their keyboard, causing it to stop working. Testing later confirmed the keyboard lacked proper waterproofing. Strict testing filters out defective products, ensuring users receive only "health-checked" mechanical keyboards.

7. Quality Control: The "Guardian Angel" of Keyboard Quality

Throughout the mechanical keyboard production process, quality control acts as a "guardian angel," protecting product quality at every step—from raw material inspection to final product testing. Each stage follows strict quality standards and inspection methods.

Take Zhuhai Hengcang Electronic Technology Co., Ltd. (a professional mechanical keyboard manufacturer) as an example. It has advanced production equipment and a dedicated quality control team. During raw material inspection, every batch of plastic, metal, and silicone is tested to ensure compliance with standards. In production, the company uses advanced quality control methods like Statistical Process Control (SPC) and Six Sigma to collect and analyze data, monitor process stability, and correct deviations in real time.

For final product testing, Hengcang conducts not only basic function checks but also evaluations of appearance, feel, and noise. For instance, optical inspection machines scan every assembled keyboard to verify details like keycap alignment (within specified tolerances) and the clarity of keycap printing (no ink smudges or misalignment). Only keyboards that pass all tests move to packaging.

8. Packaging & Shipping: The Keyboard’s Journey to You

Qualified keyboards are packaged with labels showing product model, production date, and manufacturer. The packaging acts as the keyboard’s "protective home" during transit. These keyboards are then sent to sales channels worldwide for consumers to purchase.

Before shipping, manufacturers conduct a final random inspection to ensure every batch meets quality standards. It’s like sending a child off to school—manufacturers want every mechanical keyboard to reach users in perfect condition.

From design and production to quality control, every step of a mechanical keyboard’s journey embodies the craftsmanship and effort of its makers. Like a fine work of art, it requires countless processes to refine before showcasing its full potential. We hope this guide gives you a deeper understanding of how mechanical keyboards are made and the quality control behind them. Next time you press a key, you’ll feel the dedication that went into creating your keyboard.